In this article, we will discuss a step-by-step guide on how to blow out sprinklers with air compressor. Sprinkler system is a modern method of supplying water to the irrigation fields or to the garden. Sprinkler system is similar to natural rainfall and also very effective as it consumes very less water. Sprinkler system runs through a high-pressure pump. Then water is distributed through a proper piping system to the sprinklers.

When you turn off your sprinkler system before the start of winters and want to blow out sprinklers with air compressor, there are few crucial steps to follow which we will discuss in this article.

With a pressurized blow from an air compressor, all the remaining water will be wiped out from the pipes, and all your sprinkler system will be cleared.

As air compressor generates much pressure, so it will not only help to clear the pipes, but it will also dry your pipes from inside and will prevent any water to freeze inside your sprinkler system, which otherwise would’ve caused much damage.

- How To Blow Out Sprinklers With Air Compressor

- Things you will need:

- Step by Step Guide on How to blow out sprinkler System with air compressor

- Step 1 – Turn off the Water Supply:

- Step 2 – Open Hose Bibs to Drain Water:

- Step 3 – Test your Air Compressor:

- Step 4 – Prepare the Hose:

- Step 5 – Attach the Hose:

- Step 6 – Start the Air Compressor:

- Step 7 – Monitor the Blow Out Process:

- Step 8 – Move to the Next Zone:

- Step 9 – Stop the Blow out Process:

- Step 10 – Disconnect the Fittings:

- What is Blow out Sprinkler System?

- Why it is important to Blow out Sprinkler System?

- Conclusion:

Doing an annual blow out each fall, you can save costly system repairs and maintenance cost down the line.

How To Blow Out Sprinklers With Air Compressor

Blowing out the sprinkler system through an air compressor is not only helpful before the winters, but it is also helpful if you do it periodically after every few months. A simple home garage air compressor can be used to blow out water sprinklers. It will keep all the water pipes and sprinkler nozzle clear, and will help you maintain the efficiency of sprinkler system.

Things you will need:

1- Air compressor hose

2- An adapter for the sprinkler bib

3- Protective Goggles

Step by Step Guide on How to blow out sprinkler System with air compressor

When you turn off your sprinkler system before the start of winters and want to blow out sprinklers with air compressor, there are few crucial steps to follow beforehand.

Step 1 – Turn off the Water Supply

Step 2 – Open Hose Bibs to Drain Water

Step 3 – Test your Air Compressor

Step 4 – Prepare the Hose

Step 5 – Attach the Hose

Step 6 – Start the Air Compressor

Step 7 – Monitor the Blow out Process

Step 8 – Move to the Next Zone

Step 9 – Stop the Blow out Process

Step 10 – Disconnect the Fittings

Step 1 – Turn off the Water Supply:

The first step to start the blow out process is to shut off the water supply to your sprinkler system.

This will stop the further supply of water to the pipes, so it will be easy to drain the pipes with the help of an air compressor.

After turning the water supply off, wait for few minutes before proceeding to the next steps.

Step 2 – Open Hose Bibs to Drain Water:

After shutting the water supply to your sprinkler system, the next step is to start draining your pipes manually.

This will be done by opening the hose bib which is located on the mainline of the sprinkler.

Opening the hose bib will release all the pressure which was built up inside the pipes, resulting the natural draining of air and water.

It will take few minutes until all the water is drained out from the sprinkler system, and no further water is coming out from the pipes.

The time required for this natural drainage will depend upon the size of your sprinkler system, and number of pipes and joints involved in your sprinkler system.

Step 3 – Test your Air Compressor:

Before moving to this step, make sure you’ve drained all the water naturally from the sprinkler system and no more water is coming out from the pipes.

Now bring your air compressor in the battle field 😊

Normally, all the compressors are enough to blow a medium-sized sprinkler system at once.

The amount of pressure required blowing out all pipes at once, it depends on the size of your sprinkler system and the type of pipes involved.

If your sprinkler system is made up of black polyurethane material pipes, then 50-55 pounds per square inch (PSI) is the recommended pressure.

If your sprinkler system is made up of rigid PVC material pipes, then 80-85 pounds per square inch (PSI) is the recommended pressure.

Step 4 – Prepare the Hose:

Once you’ve got to know the required PSI to blow out sprinklers with air compressor, now it’s time to prepare your hoses to connect the sprinkler system with your air compressor.

The hose must be lengthy, so it can reach your air compressor easily. Also make sure your hose is flexible, don’t have any leaks, and is able to handle the pressure from the air compressor.

Before starting your air compressor to blow out the sprinkler system, make sure your air compressor is clean from inside and don’t have any dust or mist, that can may transfer from your air compressor to the sprinkler system pipes.

So drain the drip tray and clean the filter before starting to run your air compressor.

Step 5 – Attach the Hose:

Now as your air compressor is ready along with the hose, attach the hose to the bib located on the mainline of the sprinkler system.

If the air hose isn’t properly fitting with the bib, then attach an adapter to the bib.

Because in most cases, air compressor hoses don’t directly fit with the sprinkler system’s bib.

So make sure your hose is properly connected with the sprinkler system.

Step 6 – Start the Air Compressor:

Now, the hose is properly connected with your sprinkler system and your air compressor, it’s time to proceed to starting the air compressor.

Turn off the backflow valve, and turn on the air compressor valve.

As soon as you start your air compressor, air will start flowing with pressure into the sprinkler system pipes.

The compressed air will require some time to reach all the pipes and joints of the sprinkler system.

Once it reaches the pipes and the sprinklers, you will see the water coming out from the sprinklers as a result of this pressurized air.

Be careful if there are pebbles and debris around, as it may mobilize during the blow out process.

This is why we listed the safety goggles in the required things list.

Wear the safety goggles to prevent the debris harming your eyes.

Step 7 – Monitor the Blow Out Process:

During the blow out process, keep an eye on the pressure gauge on your air compressor.

Because too much air pressure can damage your sprinkler system, as well as it can exhaust your air compressor quickly before even the task completes.

When all the water is blown out from the pipes, you will hear a change in the sound of air compressor.

Also you will notice, instead of water, now only air will start getting out from the sprinklers.

It is an indication that all the water is blown out and the pipe is now clear and dry.

If you are blowing out sprinklers with air compressor in parts, then proceed to the next zone.

Step 8 – Move to the Next Zone:

The basic reason to use air compressor in the process is to blow out the water sprinklers from the pipes with air pressure.

It is the air pressure which plays the most important role in this process.

So if you have a small air compressor and you are going to blow out your sprinkler system in multiple parts, then always start to blow out the sequence in a farthest-to-nearest order.

By doing the farthest sprinkler first, you ensure that your air compressor has the sufficient amount of air pressure to reach the farthest sprinkler.

As you continue the process, the air pressure in compressor will slow down, but now you have the nearer parts left which can easily be blow out by little air pressure.

So if you are blowing out sprinklers with air compressor in parts, then blow out the farthest sprinkler first, and then move towards the next sprinkler which should be comparatively nearer.

Step 9 – Stop the Blow out Process:

During the process, keep in mind that you have to make sure that all the water is completely blown out from the sprinkler system, and not even a single drop of water is remaining inside the pipes.

Otherwise whole effort and hardwork will go in vain.

So always double check, before moving towards the next zone.

And once you’ve completed the blow out process for all the zones, turn off your air compressor.

Step 10 – Disconnect the Fittings:

Once you’ve completely blow out the sprinklers with an air compressor, its time to finish things off.

Disconnect the hose from the sprinkler system’s bib.

Make sure the air compressor is off, and unplug it from the power source.

Roll back the hose as its work is finished now.

Congratulations! You’ve learned how to blow out sprinklers with air compressor. You can now winterize your sprinkler system yourself every year, without spending a single penny.

What is Blow out Sprinkler System?

Water is the essential component to run a sprinkler system, but at the same time, it is the water, which causes the most damage to a sprinkler system if not taken proper care.

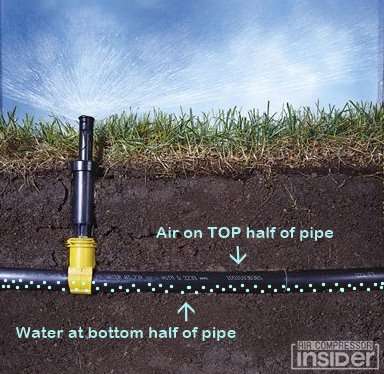

Every time, when a sprinkler system runs, even if the water supply is stopped, there is some amount of water that remains in the sprinkler system pipes (as shown in the image below).

In normal weather, this isn’t something to concern about.

But in winters, when water stars freezing down in the pipes, this little amount of remaining water becomes a very big headache.

Therefore, before you turn off your sprinkler system before the start of colder months, it is very important to have an air compressor for sprinkler blowout to prevent it from any damage during winter days.

Why it is important to Blow out Sprinkler System?

The main purpose of blowing out sprinkler system is to clear out all the little amount of remaining water from the pipes.

If this blow out process done properly, all the pipes in sprinkler system will be cleared and dried out, preventing the pipes from rot and corrode during winter months.

Many people just cover the sprinkler nozzle, valve heads with a plastic cover, thinking it will prevent their sprinkler system from freezing.

But that’s not the case. If you don’t properly blow out your sprinkler system, this water stars freezing inside the pipes, valve heads and in the sprinkler nozzle.

This freezing of water can cause a widespread damage of pipes from inside, can damage your valves, and can shatter your sprinkler nozzle.

So when you restart your sprinkler system after the winter, you will not get the same performance you experienced earlier.

And this is all because your sprinkler system is damaged from inside due to that freezing water.

Therefore, before you turn off your sprinkler system before the start of colder months, it is very important to blow out sprinkler system to prevent it from any damage during winter days.

Conclusion:

After reading this article, we hope that you’ve learnt How To Blow Out Sprinklers With Air Compressor, and after following this process step-by-step, you can prevent your sprinkler system from any damage during winter months.

We recommend you to do this process twice a year; one time before the start of winter season. And the second time before starting to reuse your sprinkler system. This will maintain your sprinkler system at its fullest and will prevent it from any sort of damage.