Five-minute read

Air compressor tanks play a vital role in storing and pressurizing compressed air, which is essential for powering various pneumatic tools.

Over time, with wear and tear, these tanks can develop leaks or other air compressor issues that compromise their capacity and safety.

Although replacing an air compressor tank may seem like a daunting task, it can be accomplished with the right tools, a good understanding of the process, and a commitment to safety.

This guide aims to provide a comprehensive overview of the steps involved in replacing an air compressor tank, helping you undertake this task with confidence and efficiency.

Replacing Air Compressor Tank

- Replacing Air Compressor Tank

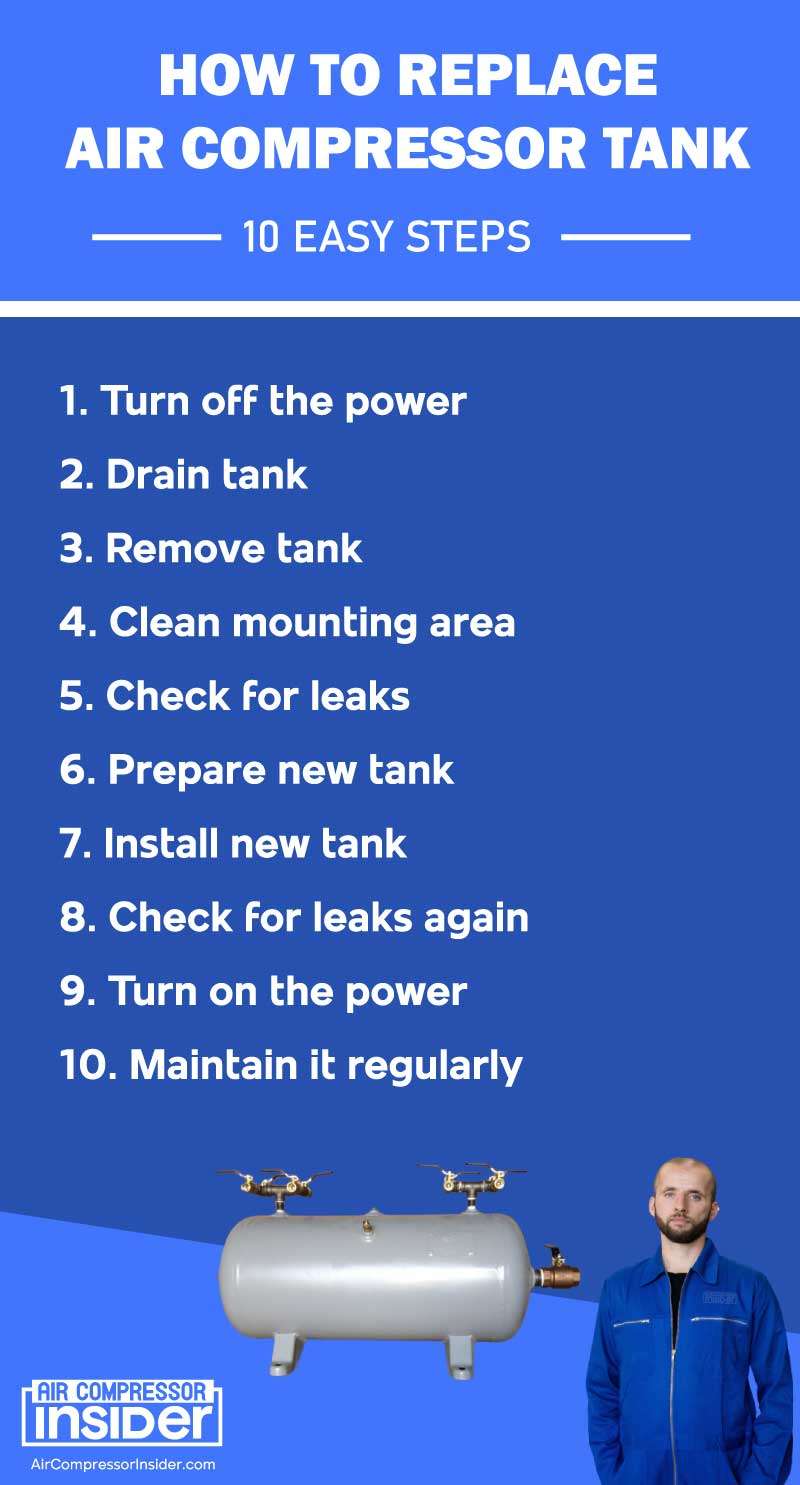

- How To Replace Air Compressor Tank – 10 Easy Steps:

- How To Know If My Air Compressor Tank Is Bad?

- Why Should I Replace My Air Compressor Tank?

- How Long Do Compressed Air Tanks Last?

- Replacing Air Compressor Tank – Factors To Consider:

- How Do You Fix A Leaking Air Compressor Tank?

- Should I look For A Used Tank For Replacing Air Compressor Tank?

- Should I Weld Instead Of Replacing Air Compressor Tank?

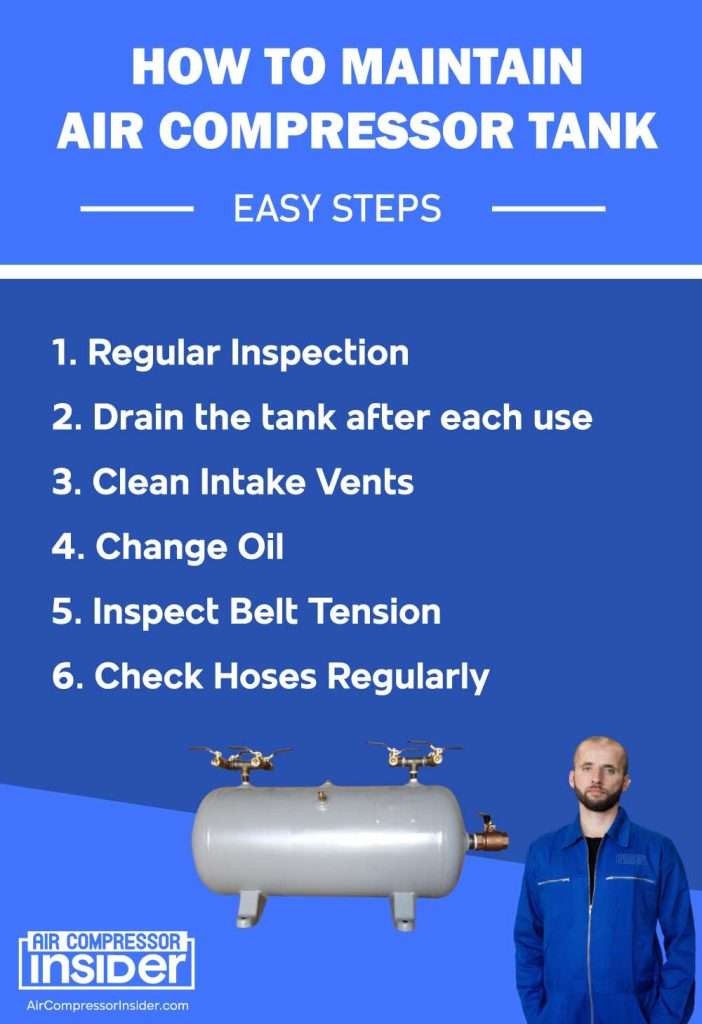

- How To Maintain An Air Compressor Tank:

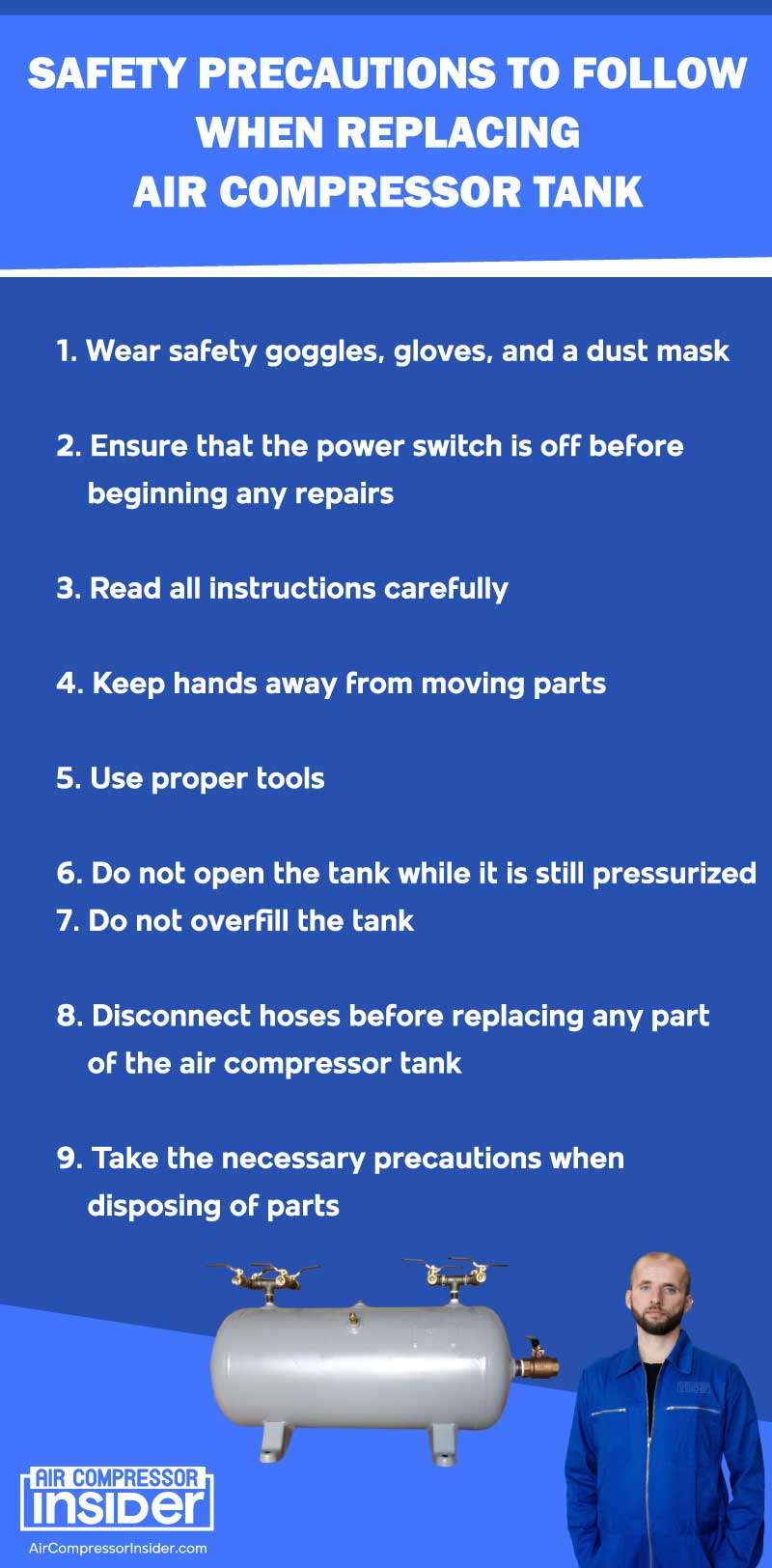

- Safety Precautions To Follow When Replacing Air Compressor Tank:

- 1. Wear safety goggles, gloves, and a dust mask:

- 2. Ensure that the power switch is off before beginning any repairs:

- 3. Read all instructions carefully:

- 4. Keep hands away from moving parts:

- 5. Use proper tools:

- 6. Do not open the tank while it is still pressurized:

- 7. Do not overfill the tank:

- 8. Disconnect hoses before replacing any part of the air compressor tank:

- 9. Take the necessary precautions when disposing of parts:

- Frequently Asked Questions

- Final Words:

When replacing air compressor tank, it’s crucial to ensure that the replacement tank has the same pressure capability as the old one.

Using a tank with a lower pressure rating can result in over-pressurization situation.

Additionally, remember to appropriately drain and depressurize the old tank before removal to prevent any accidents or damages.

Safety should always be your top priority in such operations.

How To Replace Air Compressor Tank – 10 Easy Steps:

Many people wonder about can an air compressor tank be replaced? Replacing air compressor tank seems challenging but in real it is a fairly straightforward task, Follow these simple steps to ensure you replace your air compressor tank correctly:

Step1 – Turn off power:

The first step is to turn off the power. Unplug the air compressor from the wall outlet, and if you have an electric switch be sure to turn that off as well.

Step 2 – Drain tank:

Once the power is turned off, open the drain valve and allow any remaining air in the system to escape. This is important to avoid any possible damage during the replacement process.

Step 3 – Remove tank:

Once all air has been released from the tank, remove the bolts that hold it in place and carefully lift it away from its mounting position.

Step 4 – Clean mounting area:

Before putting a new tank in place, use a damp cloth to clean away any dirt or debris from the mounting area to ensure a secure fit.

Step 5 – Check for leaks:

Before installing the new tank, check for any signs of wear or damage that may indicate a potential leak. If you find anything, it may be necessary to replace additional components in order to prevent further damage.

Step 6 – Prepare new tank:

When selecting a new tank, make sure to check the pressure rating and size of the tank to ensure compatibility with your air compressor. Once you have selected a suitable replacement, place it on a flat surface and fill it up with water. This will be used to check for any leaks before installation.

Step 7 – Install new tank:

After checking for any leaks, mount the new tank to the compressor and fasten it in place with the bolts that you removed earlier.

Step 8 – Check for leaks again:

After securing the tank, check one last time for any signs of a leak before turning on the power.

Step 9 – Power up:

Once all is secure and there are no signs of a potential leak, turn on the power and allow the system to build up pressure.

Step 10 – Maintain:

Now that your air compressor is ready to use, it’s important to remember to maintain it regularly. Check for signs of wear or damage on a regular basis and replace any worn out components as soon as possible. This will reduce the risk of any further damage, and help to ensure your air compressor runs smoothly for years to come.

How To Know If My Air Compressor Tank Is Bad?

Like many others, you may be wondering when should I replace an air compressor tank? Knowing when to replace air compressor tank is crucial for maintaining optimal performance and safety. Here are some signs to look out for:

1. Excessive Moisture:

If your tank is consistently wet or shows signs of rust, it may be time for a replacement. Moisture can cause corrosion, which weakens the tank’s structural integrity.

2. Unusual Noises:

If you start hearing strange noises from your tank, like banging or rattling, it may indicate an internal problem.

3. Reduced Performance:

A decrease in the compressor’s efficiency could be due to a faulty tank. If it’s taking longer to pressurize or holding less pressure than usual, the tank might be compromised.

4. Visible Damage:

Any visible cracks, dents, or other physical damage to the tank are serious indicators that a replacement is necessary.

Remember, always consult with a professional if you suspect your compressor tank needs replacement.

Why Should I Replace My Air Compressor Tank?

An air compressor tank plays a critical role in the operation of your air compressor. Therefore, replacing your air compressor tank at the first sign of rust or damage is essential.

Regular maintenance and cleaning of compressor tank can help extend the life of the tank, but even with diligent care, replacement will be necessary eventually.

Ultimately, the cost of replacing your air compressor tank can far outweigh the potential risks and disruptions of a failed tank.

How Long Do Compressed Air Tanks Last?

Compressed air tanks, also known as air compressors, can last anywhere from 12 to 30 years, depending on their construction quality, maintenance, and usage conditions. Regular inspections and proper care are crucial to maximizing their lifespan.

Therefore, it’s essential to regularly check the tank for any signs of wear and tear, corrosion, or damage, and to replace it as necessary to ensure safety and continued functionality.

Replacing Air Compressor Tank – Factors To Consider:

When it comes time to replace your air compressor tank, there are a few factors you should consider. These Factors are as under:

1. Size:

The replacement tank must be the same size as the original, or else it won’t fit in your compressor and could create an unsafe situation.

2. Material:

Your new tank should also be made of a material that is compatible with your air compressor and the environment you operate in.

3. Cost:

You will need to factor in the cost of the part, as well as any labor costs for installation.

4. Quality:

Ensure that you purchase a tank from a reputable manufacturer who stands behind their product and provides quality assurance.

By taking all these things into consideration when replacing your air compressor tank, you can ensure that your new tank is compatible and safe to use. Additionally, you can reduce the risk of future problems and maximize your investment in a new tank.

How Do You Fix A Leaking Air Compressor Tank?

Leaking air compressor tanks are a common issue that can be resolved with the right tools and techniques. Just follow these simple steps and you’ll soon have your compressor working safely and efficiently again.

Step 1: Shut Off the Power

Before doing anything else, make sure the power to your air compressor is switched off completely. This will prevent any potential electrical accidents or injuries while you work on it.

Step 2: Identify the Leakage

Source Once the power is off, locate the source of the leak. It may be caused by a faulty seal or damaged valve stem. If you’re unable to identify the source, don’t hesitate to contact an expert for help.

Step 3: Replace Any Damaged Parts

Once you’ve identified which parts of your air compressor tank need replacing, it’s time to get to work. Make sure you purchase the correct replacement parts for your brand and model of compressor before making any repairs.

Step 4: Reassemble the Tank

Once you have all the necessary replacement parts, carefully reassemble them onto your air compressor tank in the right order. Pay special attention to any seals or gaskets that may need to be replaced, as they are essential for preventing further leakage.

Step 5: Test the Repairs

Once you’ve reassembled your air compressor tank, it’s time to test that your repairs have been successful. Carefully switch on the power and check for any signs of leakage. If everything looks good, you should now have a functioning air compressor again!

Knowing how to fix a leaking air compressor tank is a great skill for any DIY enthusiast. If you follow these steps, you should be able to quickly and easily repair any issues with your unit in no time at all.

Should I look For A Used Tank For Replacing Air Compressor Tank?

When faced with a need to replace your air compressor tank, considering a used tank can seem like a cost-effective solution. However, several considerations should be taken into account before making this decision.

1. Price:

Used tanks may be cheaper initially, but they won’t necessarily save you money in the long run. Used tanks are often of lesser quality and require more maintenance or repairs over time, which can add up quickly.

2. Condition:

Know exactly what condition the tank is in before making a purchase. A used tank should have been thoroughly inspected for any signs of wear, corrosion, or damage. If it has any of these issues, the tank should not be used.

3. Capacity:

Make sure that a used tank is the same size as your current tank, and can hold the same amount of compressed air. A larger capacity than what you need could lead to wasted compressor power and energy costs.

4. Warranty:

Used tanks typically won’t come with a warranty. If something goes wrong with the tank you may have to replace it again at your own cost.

Ultimately, whether or not a used air compressor tank is the best choice for your needs depends on many factors. Carefully consider all of these issues before making a decision as to what kind of replacement tank you should buy. With the right information and research, you can make an informed decision that will benefit you in the long run.

Should I Weld Instead Of Replacing Air Compressor Tank?

When it comes to dealing with a damaged air compressor tank, welding may seem like a viable quick-fix. However, it’s important to consider the risks and complications that can arise from this approach.

1. Inability to Repair Internal Damage:

Welding can only be used to repair superficial damage. If the tank has sustained any internal corrosion or other damage, it must be replaced as welding will not address these issues.

2. Risk of Imperfect Welds:

Even if welded correctly, there is still a risk that the joint is not secure enough. Poorly performed welds can cause cracks and leaks in the tank.

3. Unreliable Seal:

Welding a patch to the air compressor tank does not guarantee that the seal will be reliable. In some cases, welding may actually weaken the existing seal, leading to further leaks and damage.

4. Potential for Injury or Fire:

It’s possible that sparks from welding could cause a fire or injure someone.

5. Lack of Professional Quality:

Welding a patch to the air compressor tank does not guarantee that it will look professional and aesthetically pleasing.

In conclusion, it’s important to weigh all the risks before deciding whether welding is the right approach for repairing an air compressor tank.

In most cases, replacing the tank is still the best option. It ensures that all damage is repaired and the tank is safe to use.

Replacing the tank also eliminates any potential risks associated with welding such as fire, injury or poor welds.

How To Maintain An Air Compressor Tank:

Maintaining an air compressor tank is crucial for its longevity and efficient operation. Here’s how:

1. Regular Inspection:

Regularly inspect the compressor for any signs of wear, rust, or damage. Pay special attention to the pressure relief valve and the tank’s overall condition.

2. Drain Condensation:

Moisture within the air compressor tank can lead to rusting. Ensure to drain the tank after each use to minimize moisture build-up.

3. Clean Intake Vents:

Over time, intake vents can get clogged, impacting the compressor’s efficiency. Regular cleaning of these vents is critical.

4. Change Oil (If Applicable):

If your compressor is oil-lubricated, make sure to change the oil as recommended by the manufacturer to keep the motor running smoothly.

5. Belt Tension:

Check the tension of the compressor’s belt regularly. Too loose or too tight could impact the compressor’s operations.

6. Check Hoses Regularly:

Hoses can become brittle over time. Regularly inspect them for any signs of wear or damage.

Remember that the frequency of these tasks may vary based on the usage and the manufacturer’s guidelines. Always refer to your compressor’s manual for the best practices specific to your model.

Safety Precautions To Follow When Replacing Air Compressor Tank:

It’s essential to take the necessary safety precautions when repairing an air compressor tank.

1. Wear safety goggles, gloves, and a dust mask:

Make sure that your face, hands, and any exposed skin is completely covered at all times when working on the air compressor tank.

2. Ensure that the power switch is off before beginning any repairs:

Unplug the compressor from its source of electricity and wait until it stops running before attempting to open or replace parts of the air compressor tank.

3. Read all instructions carefully:

Make sure to read through the manufacturer’s manual and follow its advice step-by-step when replacing parts or completing repairs on the air compressor tank.

4. Keep hands away from moving parts:

Be mindful that when working on an air compressor, it is easy for hands to become caught in small openings or moving parts.

5. Use proper tools:

Be sure to use the correct tools when replacing and repairing parts on an air compressor tank. Using the wrong tool can result in serious damage, injury, or even death.

6. Do not open the tank while it is still pressurized:

Pressure in a tank should always be relieved before opening for replacement of any kind.

7. Do not overfill the tank:

The air compressor tank should never be filled above the manufacturer’s stated capacity, otherwise it may cause serious damage to the compressor.

8. Disconnect hoses before replacing any part of the air compressor tank:

This will help prevent any potential leaks or explosions when attempting to replace parts.

9. Take the necessary precautions when disposing of parts:

Air compressor tanks contain hazardous materials that must be disposed of properly in accordance with local regulations.

By following these safety precautions, you can ensure your own safety while replacing or repairing an air compressor tank.

Taking the time to read through and understand all instructions prior to beginning any repairs is also essential in avoiding potential injury or damage.

Frequently Asked Questions

Question #1

How do I determine the size of an air compressor tank?

The size of an air compressor tank is determined by the capacity of the air compressor. The size and type of air tools you plan to use with your air compressor will determine the CFM (Cubic Feet per Minute) requirement, which will in turn determine the size of the air compressor tank. Generally speaking, larger tanks will provide a bigger supply of air, while smaller tanks may need to be refilled more frequently.

Question #2

What type of tank should I get for my air compressor?

The type of tank you choose should depend on the type and size of the air tools you plan to use with your air compressor. The most common types of tanks are steel and aluminum. Steel tanks tend to last longer, but they can be expensive and heavy. Aluminum tanks may be lighter and more cost effective, but they are more prone to rust over time.

Question #3

How do I know if my air compressor tank needs to be replaced

There are a few signs that can indicate that your air compressor tank may need to be replaced. One of them is rust or corrosion on the surface of the tank, which can lead to structural failure and leaks. If you notice any bulging or cracks in the metal, this could also be an indication that the tank needs to be replaced. Additionally, if you notice a decrease in air pressure, this could be another sign that your tank needs to be changed out.

Question #4

What safety precautions should I take when replacing an air compressor tank?

When replacing an air compressor tank, it is important to follow proper safety guidelines. Make sure the air compressor is unplugged from the power source and all the pressure has been released before attempting to replace the tank. Additionally, wear safety goggles and protective gloves while handling the air compressor as the edges of the metal can be sharp.

Question #5

How do I ensure a proper fit when replacing an air compressor tank?

To ensure a proper fit when replacing an air compressor tank, it is important to measure the space where the new tank will be placed. This includes measuring the diameter of the existing tank and ensuring the size of the new tank will fit in that same area. Additionally, make sure you purchase a tank with similar fittings as the old one so you do not have to get additional adapters or connectors.

Question #6

What are some tips for maintaining an air compressor tank?

Regular maintenance of your air compressor tank is essential in order to ensure optimal performance. Make sure to drain the tank after each use, as this will help prevent rust and corrosion. Additionally, it is important to check all the fittings on a regular basis to make sure they are secure and not leaking. Finally, make sure to inspect the tank for any damage or signs of wear and tear.

Question #7

What is the best way to store an air compressor tank when it is not in use?

When not in use, it is best to store your air compressor tank in a cool, dry place away from direct sunlight. You should also make sure the tank is securely mounted on a wall or other flat surface to prevent it from tipping over. Additionally, cover the tank with a protective cloth and check the fittings regularly to ensure they are secure.

Question #8

What materials can I use for an air compressor tank

The most common materials used for an air compressor tanks are steel and aluminum. Steel tanks tend to be more durable and last longer, but they can be expensive and heavier. Aluminum tanks may be more cost effective, but they are prone to rust over time. It is important to consider the type of air tools you plan to use with your air compressor when selecting a tank material.

Question #9

How do I know if an air compressor tank is safe to use?

When purchasing an air compressor tank, it is important to inspect it for any signs of damage or wear and tear. Make sure the pressure rating of the tank matches the requirements of your air tools, and check all fittings to ensure they are secure. Additionally, consider getting an ASME-certified tank, which is designed to meet safety requirements.

Question #10

Is there anything else I should know before replacing an air compressor tank?

It is important to remember that air compressor tanks can be heavy, so it may be necessary to get help when lifting and installing the new one. Additionally, make sure to buy a tank from a reputable manufacturer who offers a warranty on their products. Finally, be sure to read the instructions carefully before beginning the replacement process.

Final Words:

Replacing an air compressor tank is a fairly simple task that requires only basic tools and minimal knowledge.

With the guidance provided in this article, anyone can successfully replace their air compressor tank with confidence.

It is important to remember to always take safety precautions when working on any kind of tool or equipment.

Be sure to read the user manual for your particular model of air compressor before engaging in any maintenance or repair activities.

Additionally, always wear the proper safety gear for your job and make sure that all the parts are compatible with each other.