This comprehensive Sullair compressor troubleshooting is designed to assist you in resolving common issues that you might encounter with your Sullair Compressor.

I’ve compiled a range of solutions drawn from my years of experience in this industry, with a focus on effective, practical, and quick problem-solving techniques. This Sullair troubleshooting guide is your go-to resource for maintaining the optimal functionality and longevity of your Sullair Compressor.

- Sullair Compressor Troubleshooting

- Sullair Compressor Common Issues:

- Sullair 185 Troubleshooting

- Sullair 185 Compressor Troubleshooting – 10 Easy Steps:

- Step 1. Check Power Source:

- Step 2. Inspect Air Filter:

- Step 3. Examine Compressor Valves:

- Step 4. Listen for Abnormal Noises:

- Step 5. Test Vibration Levels:

- Step 6. Monitor Oil Level:

- Step 7. Watch Unit Temperature:

- Step 8. Use Genuine Sullair Parts:

- Step 9. Professional Maintenance:

- Step 10. Familiarize with User Manual:

- Sullair 375 Troubleshooting:

- Sullair Air Compressor Not Starting – How To Fix?

- Sullair Compressor Fault Codes:

- Sullair Compressor Troubleshooting – 25 Common Problems And Solutions:

- 1. High Discharge Temperature:

- 2. Low Oil Pressure:

- 3. High Current Draw:

- 4. Low Discharge Pressure:

- 5. Air Filter Blocked:

- 6. Low Coolant Level:

- 7. High Vibration Levels:

- 8: Low Oil Level:

- 9. Overheating Motor:

- 10. Overload:

- 11. Low Suction Pressure:

- 12. High Oil Temperature:

- 13. Low Voltage Supply:

- 14. High Ambient Temperature:

- 15. Low Refrigerant Pressure:

- 16. Leakage:

- 17. High Suction Temperature:

- 18. Stuck Compressor Valve:

- 19. Incorrect Compressor Speed:

- 20. High Refrigerant Pressure:

- 21. Low Ambient Pressure:

- 22. Overload of Electrical Components:

- 23. Low Voltage Supply:

- 24. Incorrect Compressor Direction:

- 25. Low Refrigerant Level:

- Sullair Compressor Maintenance Tips:

- Sullair Air Compressor – Worth Buying Or Not?

- Frequently Asked Questions

- Conclusion:

Sulair compressors are equipped with diagnostic fault codes to help troubleshoot any problems that arise during operation. These codes can be divided into two main categories: general faults and component-specific faults. I will discuss both these types below in detail.

Sullair Compressor Troubleshooting

Sullair compressors are known for their reliable performance, however it is still important to be aware of the signs that may indicate a problem.

Sullair Compressor Common Issues:

Common issues that can occur with Sullair compressors include low air pressure, overheating, no airflow and Sullair compressor not starting. Lets discuss each of them and start our Sullair troubleshooting.

Low Air Pressure

If your Sullair compressor is producing low air pressure, the problem could be rooted in several different locations. The most common cause of this issue is a defective or dirty air filter. Make sure to check the condition of your air filter and if necessary, replace it with a new one. Additionally, ensure that all the hoses are in good condition and well-connected. If the air pressure is still low after these steps, contact me for further assistance.

Overheating

If your Sullair compressor is running hot, check that the vents are not blocked by dirt or dust. Additionally, inspect all the hoses to make sure they have a proper fit and are free from any obstructions. If the compressor is still overheating, check the inlet valves to make sure they are open and not stuck due to dirt or rust. You may also need to replace clogged air filters or install a larger capacity cooling system for the compressor.

No Airflow

If your Sullair compressor is not producing any airflow, it could be due to a broken switch or defective wiring. Start by checking the electrical panel in your compressor and make sure all switches are in the ‘On’ position. Additionally, inspect the main power cable for any breaks or loose connections.

Compressor Not Starting

If your Sullair compressor isn’t starting, the problem could be due to a defective starter motor. Look for signs of damage or corrosion in the starter motor and replace it if necessary. Additionally, check that all cables are connected securely and there is no blockage in the air intake.

If these steps don’t work, feel free to contact me for further help with troubleshooting your Sullair compressor.

Sullair 185 Troubleshooting

When troubleshooting a Sullair 185 air compressor, there are a few common Sullair 185 air compressor problems and solutions to look out for. First, if the compressor isn’t starting, check the power source and ensure it’s properly connected. If the compressor starts but doesn’t build pressure, inspect the air filter for blockages, and examine the compressor valves for any signs of wear or damage.

In the event of abnormal noise or vibration, immediately shut off the unit to avoid further damage, and consult a professional for assessment. Remember, always refer to your user manual for specific instructions and safety guidelines.

When operating the Sullair 185 air compressor, it’s important to check the oil level regularly. Ensure that the oil is at its maximum capacity and top off with the recommended grade of lubricant if needed. It’s also essential to keep an eye on the temperature of your unit during operation. If the compressor runs too hot, shut it off right away and consult a technician for inspection.

In the event that your Sullair 185 requires maintenance, be sure to use genuine Sullair parts and accessories. Your user manual will provide you with a list of appropriate purchases for your model.

Finally, never attempt any repairs on the unit without authorized training and experience in air compressor service. Professional maintenance is the best way to ensure that your Sullair 185 is running optimally.

Overall, proper upkeep of a Sullair 185 air compressor requires regular inspection and maintenance. Always read the user manual thoroughly to become familiar with all safety procedures when operating the unit, and be sure to use genuine Sullair parts and accessories for any repair work. With consistent care, you will get many years of reliable performance from your Sullair 185.

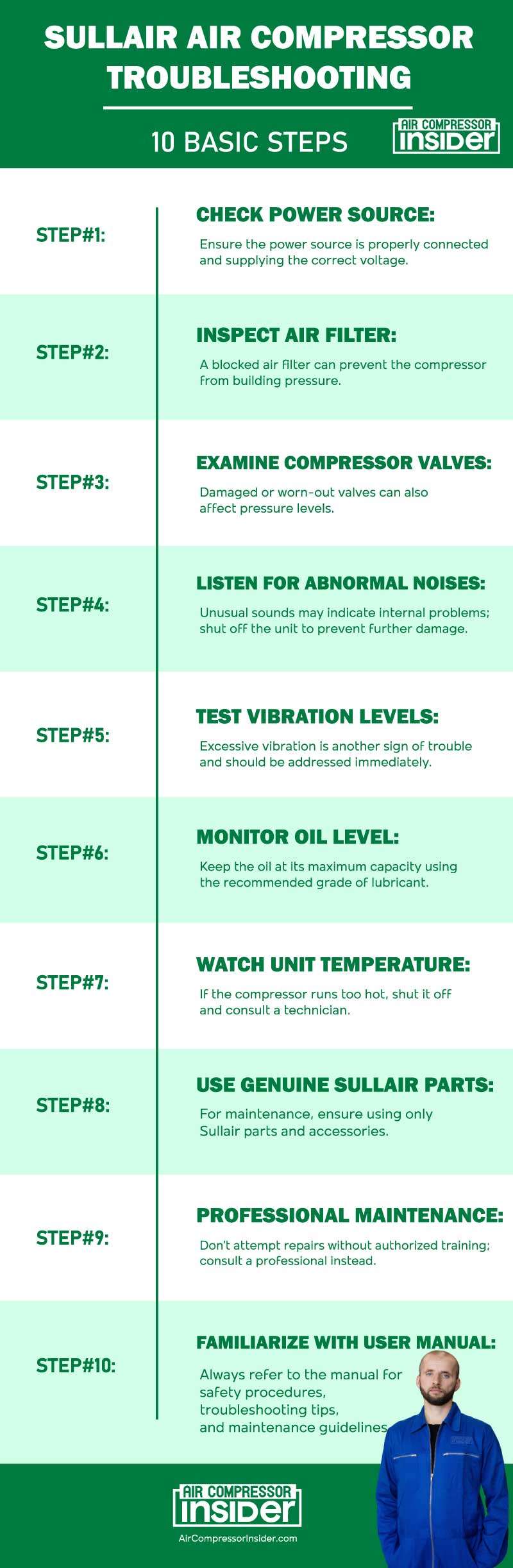

Sullair 185 Compressor Troubleshooting – 10 Easy Steps:

Here are 10 easy steps for Sullair 185 air compressor troubleshooting:

Step 1. Check Power Source:

Ensure the power source is properly connected and supplying the correct voltage.

Step 2. Inspect Air Filter:

A blocked air filter can prevent the compressor from building pressure.

Step 3. Examine Compressor Valves:

Damaged or worn-out valves can also affect pressure levels.

Step 4. Listen for Abnormal Noises:

Unusual sounds may indicate internal problems; shut off the unit to prevent further damage.

Step 5. Test Vibration Levels:

Excessive vibration is another sign of trouble and should be addressed immediately.

Step 6. Monitor Oil Level:

Keep the oil at its maximum capacity using the recommended grade of lubricant.

Step 7. Watch Unit Temperature:

If the compressor runs too hot, shut it off and consult a technician.

Step 8. Use Genuine Sullair Parts:

For maintenance, ensure using only Sullair parts and accessories.

Step 9. Professional Maintenance:

Don’t attempt repairs without authorized training; consult a professional instead.

Step 10. Familiarize with User Manual:

Always refer to the manual for safety procedures, troubleshooting tips, and maintenance guidelines.

Sullair 375 Troubleshooting:

When Sullair 375 troubleshooting, there are several common issues you may encounter.

1. No Power:

Check the connection to your power source and ensure the machine is switched on. If the circuit breaker has tripped, reset it.

2. Low or No Air Pressure:

This could be due to a leak in the air line or a problem with the compressor itself. Check the air lines for leaks and if none are found, contact a repair technician to inspect the compressor.

3. High Temperatures:

This could be due to a clogged air filter, a failed pressure switch or an overworked compressor motor. Clean the air filter regularly and inspect the pressure switch. If both of these items appear to be functioning properly, call in a repair technician as your motor may need to be replaced.

4. Compressor Not Cycling On/Off:

This could be caused by a faulty pressure switch or stuck unloader valve. Check both of these and replace them if necessary.

5. Excessive Vibrations:

This may be caused by an unbalanced compressor or loose connection on the motor. Inspect the motor mountings for any signs of wear and tear. If the problem persists, call in a repair technician as this could be an indication of a more serious underlying issue.

In addition to the common issues outlined above, it is important to regularly maintain your Sullair 375 compressor. This will help reduce the chance of any major problems from developing and also keep the machine running efficiently for longer periods of time. Regular maintenance includes changing the oil, inspecting and cleaning the air filter, and checking all connections for any signs of wear.

Additionally, be sure to check that there are no leakages in the intake or exhaust lines, as these can lead to a decrease in performance and efficiency.

By following this basic troubleshooting guide and performing regular maintenance on your Sullair 375, you can help ensure that your compressor runs smoothly for years to come.

Sullair Air Compressor Not Starting – How To Fix?

If your Sullair Air Compressor is not starting, there could be several underlying reasons. Follow these steps and do Sullair air compressor troubleshooting easily.

1. Power Supply Issues:

Verify that your Sullair Air Compressor is properly connected to a power source. Check the power cords for any visible signs of damage. Make sure the circuit breaker has not tripped. If you discover any problems with the power supply, rectify them and try starting the compressor again.

2. Pressure Switch Malfunction:

If the pressure switch is not functioning correctly, it might not signal the motor to start. Inspect the pressure switch, and if necessary, replace it.

3. Motor Problems:

If the motor of the air compressor is defective or worn out, it might fail to start. Consider seeking professional help for motor-related issues.

4. Faulty Compressor Pump:

If your pump is faulty, it could lead to the compressor failing to start. Check for wear and tear and replace the pump if needed.

5. Blocked Air Intake:

Ensure the air intake isn’t blocked. Clean it regularly to prevent any obstructions.

6. Overheating:

If the compressor has recently been in use and is now failing to start, it could be due to overheating. Allow it to cool down before attempting to restart.

7. Faulty Capacitor:

A defective capacitor might hinder the starting of the motor. In this case, replacing the capacitor might solve the problem.

8. Incorrect Pressure Setting:

Ensure that the pressure settings are correct. An over or under setting might lead to the compressor not starting.

9. Lack of Oil Lubrication:

Insufficient oil lubrication can lead to friction in the motor, causing it not to start. Check the oil levels and refill if necessary.

10. Worn Out Belts:

Worn out or broken belts can cause the compressor to fail to start. Replace them if needed.

Remember to always refer to your Sullair Air Compressor manual or consult with a professional if you are unsure about performing these checks and repairs.

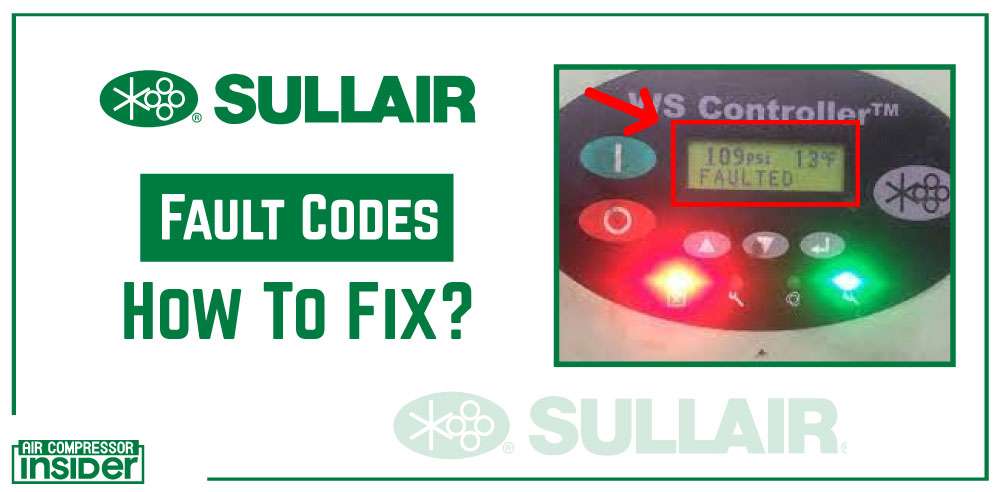

Sullair Compressor Fault Codes:

Sulair compressors are equipped with diagnostic fault codes to help troubleshoot any problems that arise during operation. These codes can be divided into two main categories: general faults and component-specific faults.

General Faults are errors that occur when the compressor is not functioning optimally, possibly due to a lack of airflow or power supply. Examples include air-leakage faults, compressor overloads, and air pressure failures.

Component-specific Faults occur when a specific component within the compressor fails to operate properly. These could include motor faults, valve problems, oil system issues, and filter blockages.

It is important to note that Sullair compressors are also equipped with warning codes which indicate that there is an issue, but the compressor is still able to operate normally. Examples of warning codes include low oil pressure, high discharge temperature, and reduced maximum pressure.

To ensure that your Sullair compressor is running smoothly, it is important to monitor for signs of fault or warning codes on a regular basis. If a fault code appears during operation, it should be addressed immediately to avoid further damage to the compressor.

To assist with troubleshooting, Sullair provides online resources such as checklists and service manuals that provide detailed information on fault codes and their solutions. Additionally, trained technicians can be contacted for more in-depth assistance if necessary.

1. Error Code F1:

This code indicates an issue with the motor rotation. If the motor is not turning in the correct direction, it will trigger this fault code.

2. Error Code F2:

This is a temperature warning code. If the compressor is running hotter than the safe threshold, it will display this fault.

3. Error Code F3:

This code typically indicates an oil pressure problem. If the oil pressure is too low or too high compared to the set point, this fault code is displayed.

4. Error Code F4:

If the compressor is operating at a higher pressure than its rated capacity, the F4 fault code is triggered.

Please note these are common Sullair Compressor fault codes. Each fault requires careful diagnosis and should be resolved promptly to prevent further damage. It’s recommended to consult the compressor’s manual or contact a professional service for repair.

Sullair Compressor Troubleshooting – 25 Common Problems And Solutions:

There are several common problems that can occur with a Sullair compressor. Here are some of the more frequent issues and their solutions.

1. High Discharge Temperature:

This fault can be caused by low coolant levels, blocked or dirty coolant lines, or faulty temperature sensors.

2. Low Oil Pressure:

A potential cause of this issue could be an oil leak in the system, a faulty oil pump, or blocked oil filters causing a pressure drop.

3. High Current Draw:

This can be caused by a short circuit in the motor, a faulty compressor motor, or high compressor load due to external factors.

4. Low Discharge Pressure:

This may be due to a leak in the discharge line, a faulty pressure sensor, or a failed valve causing the pressure to drop.

5. Air Filter Blocked:

This fault is usually caused by a dirty or clogged air filter, requiring replacement or cleaning.

6. Low Coolant Level:

Refilling the coolant in the system is necessary to avoid damage and ensure proper operating temperatures.

7. High Vibration Levels:

This could be caused by an imbalance in the rotor or compressor pump, misalignment of motor or compressor components, or foundations that are not properly secured.

8: Low Oil Level:

Refilling the oil in the system is necessary to maintain proper lubrication and avoid damage.

9. Overheating Motor:

This fault could be caused by a faulty fan, blocked air intake or exhaust, or an electrical issue with the motor itself.

10. Overload:

This can be caused by an external load on the compressor, such as a large number of tools or machinery.

11. Low Suction Pressure:

This could be due to a leak in the suction line, a faulty pressure sensor, or a failed valve causing the pressure to drop.

12. High Oil Temperature:

This fault can be caused by low coolant levels, blocked or dirty coolant lines, or faulty temperature sensors.

13. Low Voltage Supply:

This could be due to a poor electrical connection, wiring faults, or a faulty power source.

14. High Ambient Temperature:

Higher ambient temperatures can cause the compressor to overheat, and should be monitored closely.

15. Low Refrigerant Pressure:

This could be due to a leak in the system, faulty pressure sensor, or a failed valve causing the pressure to drop.

16. Leakage:

This fault can be caused by worn seals, loose connections, damaged components, or a failing compressor.

17. High Suction Temperature:

This fault can be caused by low coolant levels, blocked or dirty coolant lines, or faulty temperature sensors.

18. Stuck Compressor Valve:

This issue could be caused by a defective valve, an electrical problem with the motor, or debris blocking the valve.

19. Incorrect Compressor Speed:

This fault can be caused by a defective motor, an incorrect signal from the controller, or faulty wiring.

20. High Refrigerant Pressure:

This can be caused by a leak in the system, faulty pressure sensor, or a failed valve causing the pressure to rise.

21. Low Ambient Pressure:

This could be caused by an obstruction in the intake, a faulty pressure sensor, or insufficient ventilation.

22. Overload of Electrical Components:

This can be caused by excessive load on the compressor motor from external sources, such as large numbers of tools or machinery.

23. Low Voltage Supply:

This could be due to a poor electrical connection, wiring faults, or a faulty power source.

24. Incorrect Compressor Direction:

This fault can be caused by an incorrect signal from the controller, a defective motor, or faulty wiring.

25. Low Refrigerant Level:

Refilling the refrigerant in the system is necessary to avoid damage and ensure proper operating temperatures.

It is important to note that these fault codes can be indicative of a wide range of issues, and should not be taken as conclusive evidence of a specific problem. Due to the complexity of compressor systems, it is recommended to consult an expert if any of these fault codes are present. Additionally, regular maintenance and servicing of compressors is essential to ensure optimal performance and avoid unexpected faults and failures.

Sullair Compressor Maintenance Tips:

Regular maintenance of your Sullair compressor is essential for ensuring optimal performance and reliability.

1. Check air filters:

Every now and then, you should check the air filters, inlet valves and other components for any dirt or obstructions.

2 Clean out dust and debris:

Make sure to clean out any dust or debris from the vents so that air can flow freely. It’s also a good idea to inspect all hoses for signs of wear and tear, and replace them if necessary.

3. Check the electrical panel:

Lastly, check the electrical panel to ensure that all switches are in the correct positions. With these simple maintenance tips, you can keep your Sullair compressor running at its best for a long time to come.

Keep in mind that any repairs or maintenance should always be done by a qualified professional. If you’re unsure how to proceed, don’t hesitate to contact me for expert assistance with your Sullair compressor. I can provide specialized advice and make sure that your compressor is running optimally.

Remember, taking the time and effort to properly maintain your Sullair compressor will be well worth it in the long run. So don’t neglect regular maintenance and make sure to take the proper steps when troubleshooting your compressor issues. With the right maintenance, you can keep your Sullair compressor running smoothly for many years to come.

Sullair Air Compressor – Worth Buying Or Not?

The Sullair air compressor is a reliable and powerful choice for many professionals. It’s designed for heavy-duty use and is capable of powering a variety of applications. The Sullair air compressor is backed by a strong warranty and excellent customer service, so you can be sure you’re getting a quality product.

The compressor also has a long life expectancy and is built to last. It’s also relatively quiet compared to other models on the market, and its energy efficiency helps to reduce operating costs.

Overall, the Sullair air compressor is a great choice for those looking for a reliable, powerful, and cost-effective solution.

However, the Sullair air compressor is not for everyone. For those who require a low capacity or lower power output, there are other models available that might better suit their needs.

Additionally, some users have reported issues with the customer service and warranty coverage that comes with this product, which may be something to consider before making a purchase.

Overall, the Sullair air compressor is definitely worth considering if you’re looking for a reliable, powerful, and cost-effective solution. However, it’s important to take into consideration the customer service issues as well as your own specific requirements before making a final decision.

With some research and comparison shopping, you can find the compressor that best fits your needs and budget. And with proper maintenance and care, your Sullair air compressor can provide reliable power for years to come.

When it comes to maintenance of the Sullair air compressor, there are a few things you should keep in mind. Regularly checking the oil levels and replacing any worn or damaged parts will help ensure that your unit is functioning properly.

As you can see, the Sullair air compressor is a great choice for those looking for reliable power and cost-efficiency. With proper maintenance and care, it can provide years of service.

However, before making a final purchase decision, make sure to consider all factors and evaluate your own specific needs. Doing so will help you make the right choice for your home or business.

In conclusion, the Sullair air compressor is an excellent choice for many applications and is backed by great customer service and warranty coverage. If you’re looking for reliable power at a reasonable cost, the Sullair air compressor is worth considering.

Frequently Asked Questions

Question #1

What is the main cause of oil leaks on Sullair compressors?

The most common cause of oil leaks from a Sullair compressor is worn gaskets and seals that need to be replaced. It could also be due to a dirty or clogged air-oil separator, which should also be checked and cleaned if necessary.

Question #2

What causes excessive noise from a Sullair compressor?

Excessive noise can be caused by worn or unbalanced fan blades, as well as having incorrect belt tension or bearing failure. It is also possible that the intake silencer, exhaust muffler, or air filter are clogged and need to be cleaned.

Question #3

How do I check for proper air flow in a Sullair compressor?

The first step is to ensure that the intake and discharge valves are open, as well as making sure any vents or drains are clear. The next step is to test the pressure drop across the intake filter element, which should not exceed specified limits. Finally, you can measure the air velocity at various points in the system to ensure it is within acceptable limits.

Question #4

What should I do if my Sullair compressor is losing pressure?

The most common cause of pressure loss is a faulty air-oil separator, which should be checked and replaced if necessary. It could also be due to a clogged filter element or dirty intake valves, so these components should also be checked and cleaned if necessary.

Question #5

What causes poor performance from a Sullair compressor?

Poor performance can be the result of an incorrect air-oil ratio, which should be check and adjusted as necessary. It could also be due to worn or clogged intake valves, a weak motor, or insufficient motor voltage.

Question #6

How often should the oil filter of a Sullair compressor be replaced?

The oil filter on a Sullair compressor should generally be replaced every 500-1000 hours, depending on operating conditions and how dirty the air intake is. It is also important to check the filter element for any clogging or wear and replace it as necessary.

Question #7

How should I go about troubleshooting a Sullair compressor?

Troubleshooting a Sullair compressor generally involves checking for any clogged or worn components, such as the air-oil separator, intake valves, filter element, and motor. It is also important to check the air-oil ratio and adjust it as necessary.

Question #8

What is the best way to maintain a Sullair compressor?

The best way to maintain a Sullair compressor is to regularly check for any wear or clogging in components, such as the air-oil separator, intake valves, filter element, and motor. It is also important to check the air-oil ratio and adjust it as necessary. Additionally, the oil should be changed regularly and the filter element replaced every 500-1000 hours, depending on operating conditions.

Question #9

How can I tell if the motor of a Sullair compressor is failing?

The most common sign of a failing motor in a Sullair compressor is an increase in electrical current draw, which indicates that the motor is not able to provide enough power. This can also be accompanied by a decrease in air pressure and an increase in operating temperature.

Question #10

What should I do if the air-oil ratio of my Sullair compressor is too high?

If the air-oil ratio is too high, it can lead to poor performance and even damage to the compressor. In this case, you should check the oil level and adjust it as necessary. If the oil level is correct, then it may be a sign that the air-oil separator needs to be replaced.

Conclusion:

I hope this Sullair troubleshooting guide has been useful for Sullair compressor troubleshooting your issues. If you’re still having problems, don’t hesitate to contact me and I’ll be more than happy to help you get your machine up and running again. With our expert guidance and support, you can be sure that your Sullair compressor will operate as good as new.