A 60Gallon Air Compressor is a versatile tool with a wide array of applications in both home and professional settings.

With its significant air capacity and potent power, it can operate high-demand air tools such as sanders, grinders, paint sprayers, and pneumatic wrenches efficiently.

It’s ideal for tasks in automotive repair shops, manufacturing factories, and home improvement projects, serving as an integral part of spray painting, sandblasting, and inflating tires.

In short, a 60 gallon tank size air compressor can handle prolonged and heavy-duty tasks without frequent stops, thus enhancing productivity.

- 60 Gallon Air Compressor – Good For Air Tools?

- Can a 60 Gallon Air Compressor run a Nail Gun?

- Can a 60 Gallon Air Compressor Run An Impact Wrench?

- Can a 60 Gallon Air Compressor Run A Framing Nailer?

- Is 60 Gallon Air Compressor Good For Tires?

- Can You Paint With 60 Gallon Air Compressor?

- Can You Use 60 Gallon Air Compressor To Paint A Car?

- Will a 60 Gallon Air Compressor Run A Paint Sprayer?

- How Many PSI is 60 Gallon Air Compressor?

- How Much Does 60 Gallon Air Compressor Weigh?

- How Long Do 60 Gallon Air Compressors Last?

- Should I Buy 60 Gallon Air Compressor?

- How To Use 60 Gallon Air Compressor?

- Maintenance Tips For 60 Gallon Air Compressor:

- Frequently Asked Questions

- Final Words:

60 Gallon Air Compressor – Good For Air Tools?

A 60Gallon Air Compressor can indeed be a good fit for air tools. This type of compressor is powerful enough to handle most air tools, making it a versatile choice for both professional and DIY applications.

The large tank allows for continuous operation without the need for frequent stops and starts. This translates to consistent delivery of pressurized air, driving the performance of various air tools such as impact wrenches, air ratchets, and paint sprayers.

However, it’s always important to consult the specific air requirements of each tool to ensure the compressor can meet their demand.

A 60Gallon Air Compressor is a versatile tool that can power a multitude of air tools.

It can comfortably handle the demands of tools such as air drills, impact wrenches, sanders, grinders, paint sprayers, and nail guns.

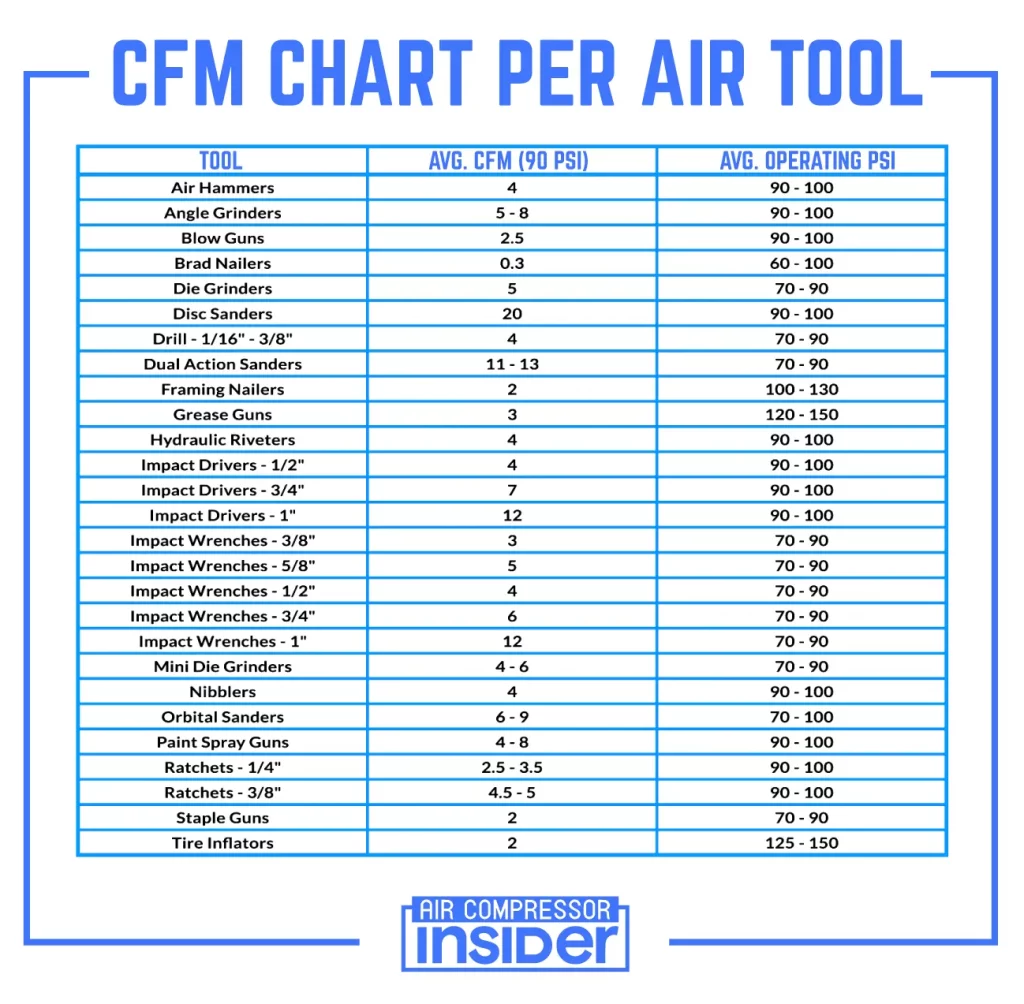

More robust and high-demand tools like sandblasters or abrasive blasters may also be supported, but the extent to which these tools can be used will depend on their specific CFM (cubic feet per minute) ratings, which should ideally match or be lower than the compressor’s CFM.

Always remember to check the CFM requirements of each tool to ensure compatibility with your 60Gallon Air Compressor.

Can a 60 Gallon Air Compressor run a Nail Gun?

Yes, a 60Gallon Air Compressor can run a nail gun. The capacity of an air compressor is measured in gallons, which represents the volume of air it can hold.

A 60Gallon Air Compressor provides ample air volume necessary to operate a nail gun effectively.

However, it’s not solely the tank size that’s important, but also the compressor’s CFM (Cubic Feet per Minute) and PSI (Pounds per Square Inch) ratings, which should align with the requirements of the nail gun.

Thus, while a 60Gallon Air Compressor can power a nail gun, it’s essential to ensure the compressor’s output matches the nail gun’s specifications for optimal performance.

Can a 60 Gallon Air Compressor Run An Impact Wrench?

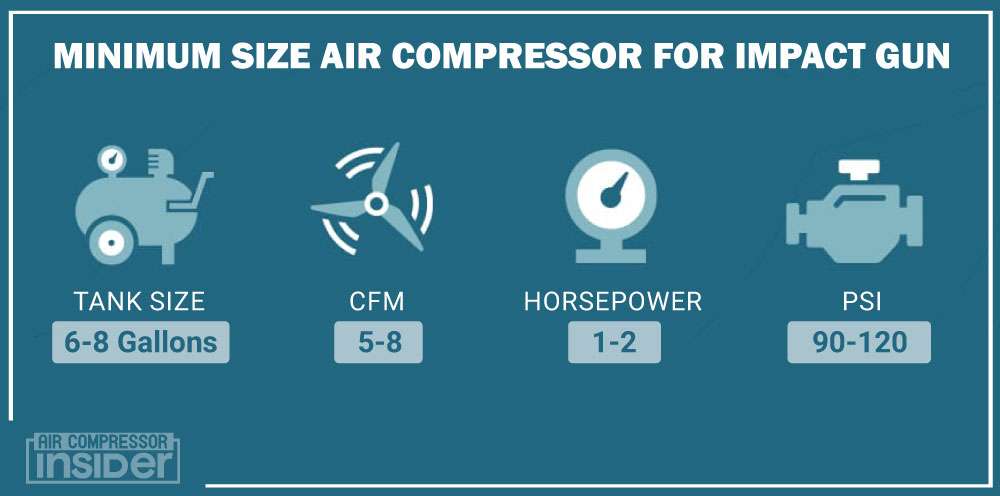

Yes, a 60 gallon air compressor can effectively run an impact wrench. The key is to ensure that the air compressor can deliver the required Cubic Feet per Minute (CFM) at the correct pressure (PSI) that the particular impact wrench demands.

Most common impact wrenches require a moderate CFM rating which a 60 gallon air compressor can typically provide.

It’s always recommended to check the individual specifications of your tools and make sure they align with the capabilities of your air compressor. In this way, you can ensure optimal performance and longevity of your tools.

Can a 60 Gallon Air Compressor Run A Framing Nailer?

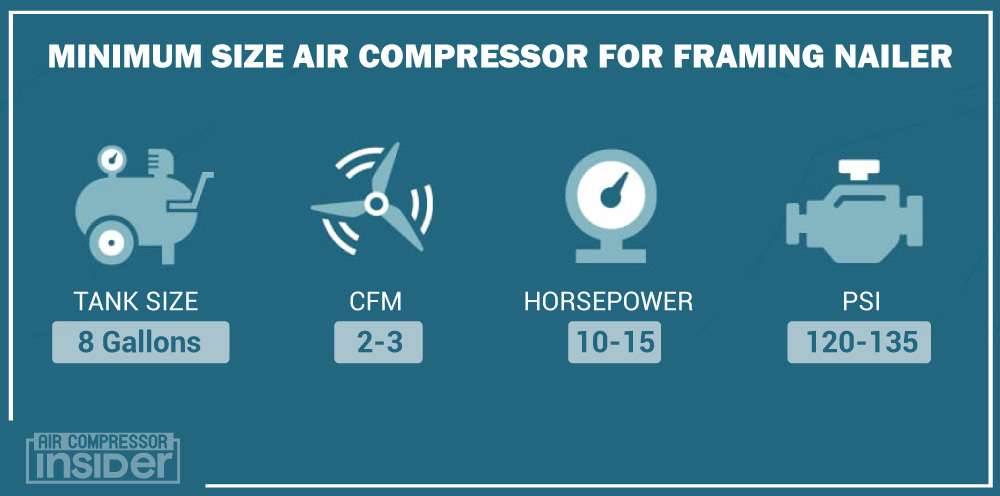

Yes, a 60Gallon Air Compressor can run a framing nailer. Air tools, such as framing nailers, require a certain amount of air pressure to operate effectively, measured in pounds per square inch (PSI).

The majority of framing nailers require between 70 and 120 PSI, which a 60Gallon Air Compressor can comfortably provide.

However, it’s always recommended to check the manufacturer’s specifications of both the compressor and the nailer to ensure compatibility.

Furthermore, a 60-gallon compressor is advantageous as it provides a large reserve of compressed air, allowing you to use the nailer for extended periods without frequent compressor cycles.

Is 60 Gallon Air Compressor Good For Tires?

A 60Gallon Air Compressor is generally more than sufficient for inflating tires. These machines typically generate air pressure measured in PSI (Pounds per Square Inch), with most car and bicycle tires requiring less than 50 PSI.

A 60Gallon Air Compressor can generate significantly more than this, making it not only suitable for inflating tires but also for powering air tools.

It’s important to note that while the compressor is powerful, the actual inflation speed will depend on the specific model and its CFM (Cubic Feet per Minute) rating. Always refer to the manufacturer’s instructions for optimal usage.

Can You Paint With 60 Gallon Air Compressor?

Yes, you can indeed paint with a 60 gallon air compressor. A 60 gallon air compressor is typically suitable for most automotive and industrial painting jobs.

This sizable air compressor can maintain a steady and consistent air pressure, which is essential for achieving a smooth and even paint job.

It is important, however, to consider the specific requirements of your painting tools and the scope of your project.

Some high-volume, low-pressure (HVLP) paint sprayers, for instance, may require a compressor with a higher CFM (cubic feet per minute) rating.

Therefore, always check the specifications of your tools before starting your painting project.

Can You Use 60 Gallon Air Compressor To Paint A Car?

Yes, you can use a 60Gallon Air Compressor to paint a car. A 60Gallon Air Compressor is often recommended for painting automotive parts because it provides the right amount of power and pressure for atomizing the paint, resulting in smooth and even coverage.

It also ensures a continuous and consistent supply of pressurized air, reducing the risk of intermittent spraying which can lead to uneven paint application.

Remember though, the quality of the paint job also depends on factors like the type of spray gun, the paint, and the technique used.

Will a 60 Gallon Air Compressor Run A Paint Sprayer?

Yes, a 60Gallon Air Compressor can run a paint sprayer. The capacity of an air compressor is an important factor when it comes to painting as it determines the amount of air the compressor can hold and deliver.

A 60Gallon Air Compressor offers a large enough capacity to effectively power a paint sprayer for extended periods, making it ideal for larger painting projects.

However, it’s crucial to also consider the compressor’s PSI (pounds per square inch) and CFM (cubic feet per minute), as these specifications need to match the requirements of the paint sprayer for optimal performance.

How Many PSI is 60 Gallon Air Compressor?

The PSI (Pounds per Square Inch) of a 60Gallon Air Compressor can vary greatly depending on the specific model and manufacturer.

However, most 60Gallon Air Compressors have a maximum pressure range between 135 to 175 PSI. It’s crucial to refer to the user manual or manufacturer’s specifications for the most accurate information regarding your specific air compressor.

Always ensure to operate your air compressor within the recommended PSI range to maintain safety and prolong the lifespan of the tool.

How Much Does 60 Gallon Air Compressor Weigh?

The weight of a 60Gallon Air Compressor can vary greatly depending on the model, brand, and specific features.

Generally, these units can weigh anywhere from 200 to over 300 pounds. For instance, a basic model from a reputable manufacturer might weigh approximately 247 pounds, while a high-end, feature-rich model from the same brand might tip the scales at around 305 pounds.

Always refer to the specific product specifications for the most accurate information. Please remember to take this into account when planning for transportation and installation, and ensure you have the necessary equipment and manpower to handle the weight safely.

How Long Do 60 Gallon Air Compressors Last?

The lifespan of a 60Gallon Air Compressor can vary greatly depending on several factors. If maintained properly, it can last between 10 to 15 years, or even longer.

Key factors influencing its longevity include the quality of the compressor, frequency of use, the environment it’s used in, and adherence to the recommended maintenance schedule.

Regular servicing and proper usage can significantly extend the life of your compressor, making it a long-term investment.

This involves checking and replacing parts when necessary, keeping it clean, and ensuring it operates within its capacity.

Should I Buy 60 Gallon Air Compressor?

When it comes to the value proposition of 60Gallon Air Compressors, it largely depends on the individual’s specific needs and applications.

These units are typically designed for heavy-duty use in commercial and industrial settings, where continuous, high-powered air supply is required.

Their large tank capacity ensures that the air pressure is consistent, thus reducing the frequency of motor startups. This not only helps in prolonging the compressor’s life but also results in energy savings.

However, these advantages come with a higher initial cost and space requirements compared to smaller units.

Therefore, if your tasks involve high-volume air tools such as sanders or grinders, or if you run a business that requires extensive use of pneumatic equipment, a 60Gallon Air Compressor could be a worthwhile investment.

Conversely, for sporadic, light-duty tasks, a smaller and more portable air compressor might be more cost-effective.

How To Use 60 Gallon Air Compressor?

Utilizing a 60 gallon air compressor can be straightforward if you follow a few simple steps:

1. Ensure Safety:

Before you start using the air compressor, make sure the work area is clean, well-ventilated, and free from any flammable materials. Always wear appropriate safety gear such as safety glasses and ear protection while operating the compressor.

2. Check Oil Level:

Some 60 gallon air compressors are oil-lubricated. Check the oil level through the oil sight glass located on the side of the compressor. If needed, top up with the compressor-specific oil.

3. Connect the Hose:

Connect your air hose to the compressor’s air outlet. Ensure that the connection is secure to prevent any air leakage.

4. Set The Pressure:

Adjust the pressure regulator knob to set the desired pressure level. Make sure not to exceed the maximum pressure rating of your air tools.

5. Turn ON the Air Compressor:

Flip the power switch to the ‘on’ position. The compressor will start to fill the tank with compressed air.

6. Use Your Air Tool:

Once the compressor has reached the desired pressure, you can begin using your pneumatic tools. Remember to turn off the compressor and release any remaining air pressure when you have finished.

7. Shut Down:

Once you are finished with your task, turn off the air compressor, disconnect the air tool or accessory, and slowly open the tank drain valve to release any condensation.

Remember, always refer to the specific instruction manual of your 60 Gallon Air Compressor for more detailed steps and safety guidelines.

Maintenance Tips For 60 Gallon Air Compressor:

When it comes to maintaining your 60Gallon Air Compressor, there are several key points to keep in mind.

1. Regularly Check and Change Air Filters:

Dirt and debris can reduce the efficiency of your air compressor. Regularly check and clean or replace the filters to ensure optimal performance.

2. Monitor Oil Levels:

For oil-lubricated air compressors, regularly check and maintain the appropriate oil level.

3. Regularly Drain Moisture from Tanks:

Compressing air generates moisture which can lead to corrosion. Ensure to drain the tanks regularly to avoid this.

4. Check Hoses Regularly:

Hoses can degrade over time and could potentially leak air. Regularly inspect and replace them if needed.

5. Clean Intake Vents:

Keep your intake vents as clean as possible to ensure the air compressor can draw in air efficiently.

6. Check for Leaks:

Even a small leak can impact the efficiency. Perform periodic checks and seal any leaks.

7. Keep Unit Clean:

Keep the compressor clean from dust and debris as it can cause overheating and other issues.

8. Check and Replace the Belt, if Needed:

Over time, the belt can wear out. Check and replace it if you notice any signs of wear.

9. Regular Maintenance Checks:

Regularly perform a general inspection of the compressor for any visible issues or potential problems.

10. Consult the Owner’s Manual:

Always refer to the owner’s manual for specific maintenance instructions for your model.

Frequently Asked Questions

Question #1

What is a 60Gallon Air Compressor used for?

A 60Gallon Air Compressor is versatile and is typically used for heavy-duty tasks such as powering air tools, inflating tires, and even for painting and sandblasting.

Question #2

How much power does a 60Gallon Air Compressor need?

Most 60Gallon Air Compressors require a power supply of 220-240 volts.

Question #3

How much does a 60Gallon Air Compressor weigh?

The weight can vary based on the model but expect it to be in the range of 200-300 pounds.

Question #4

What is the cost of a 60Gallon Air Compressor?

The price of a 60Gallon Air Compressor can range from $500 to $2000 depending on the brand, model, and features.

Question #5

How loud is a 60Gallon Air Compressor?

The noise level of 60Gallon Air Compressors is often measured in decibels (dB). On average, they range from 70-90 dB, but this can vary based on the model and brand.

Question #6

Can I use a 60Gallon Air Compressor at home?

Yes, but keep in mind that they are larger and louder than smaller models, making them better suited for a garage or workshop.

Question #7

How long does a 60Gallon Air Compressor take to fill up?

The time can vary based on the compressor’s pump, but most 60-gallon models will fill up in 5-7 minutes.

Question #8

What type of maintenance is required for a 60Gallon Air Compressor?

Regular maintenance for a 60Gallon Air Compressor includes draining the tank to prevent moisture build-up, cleaning the intake vents, and checking the oil levels if it is an oil-lubricated model.

Question #9

Is a 60Gallon Air Compressor suitable for painting?

Yes, a 60Gallon Air Compressor can provide the continuous air flow needed for spray painting.

Question #10

What is the life expectancy of a 60Gallon Air Compressor?

The lifespan of a 60Gallon Air Compressor can greatly vary, but with proper maintenance, many can last 10-15 years or more.

Final Words:

In conclusion, a 60Gallon Air Compressor is a robust, versatile tool that is particularly beneficial for heavy-duty tasks.

Its utility spans numerous applications, from powering air tools to inflating tires, and even facilitating painting and sandblasting jobs.

However, with its impressive capabilities come certain responsibilities – it requires regular maintenance to ensure optimal performance and longevity.

By carefully adhering to the maintenance tips outlined above and referring to your specific model’s owner’s manual, you can maximize the efficiency and lifespan of your 60Gallon Air Compressor.

Whether you’re a professional contractor or a dedicated DIY enthusiast, a 60Gallon Air Compressor can be a powerful asset in your toolkit.