An 8Gallon Air Compressor is a versatile tool with numerous applications across a wide range of industries, including automotive, construction, woodworking, and even home DIY projects. It generates pressurized air, which can be used to power pneumatic tools such as nail guns, impact wrenches, paint sprayers, and air ratchets.

Moreover, it can be used for inflating tires, spray painting, sandblasting, and even cleaning hard-to-reach areas with a blast of compressed air. Its 8-gallon tank size strikes a balance between portability and air capacity, making it a popular choice for both professionals and hobbyists.

- 8 Gallon Air Compressor – Good For Air Tools?

- Can a 8 Gallon Air Compressor run a Nail Gun?

- Can a 8 Gallon Air Compressor Run An Impact Wrench?

- Can a 8 Gallon Air Compressor Run A Framing Nailer?

- Is 8 Gallon Air Compressor Good For Tires?

- Can You Paint With 8 Gallon Air Compressor?

- Can You Use 8 Gallon Air Compressor To Paint A Car?

- Will a 8 Gallon Air Compressor Run A Paint Sprayer?

- How Many PSI is 8 Gallon Air Compressor?

- How Much Does 8 Gallon Air Compressor Weigh?

- How Long Do 8 Gallon Air Compressors Last?

- Should I Buy 8 Gallon Air Compressor?

- How To Use 8 Gallon Air Compressor?

- Maintenance Tips For 8 Gallon Air Compressor:

- Frequently Asked Questions

- Final Words:

8 Gallon Air Compressor – Good For Air Tools?

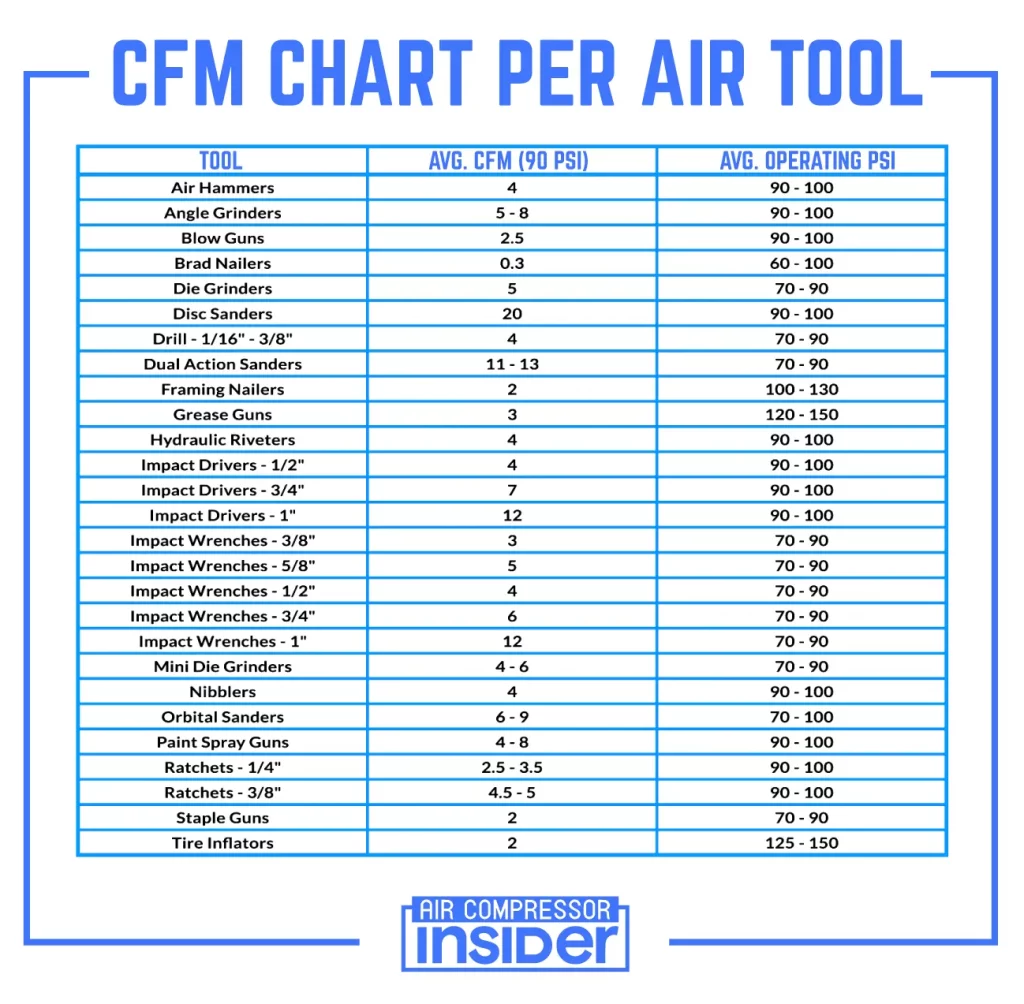

Absolutely, an 8 gallon air compressor tank is often sufficient for many air tools. This is due to the fact that these compressors can typically deliver between 3.7 to 4.8 CFM (Cubic Feet per Minute) at 90 PSI (Pounds per Square Inch), which is within the operational range of many common air tools. This includes tools such as brad nailers, framing nailers, and even some impact wrenches and paint sprayers.

However, it’s important to note the specifications of your specific tools to ensure they are compatible with the compressor’s output. Always remember, for tools that require a higher CFM, or for continuous use of tools, a larger compressor may be needed to avoid the risk of under-powering your tools.

Many air tools can be powered using an 8Gallon Air Compressor. These include, but are not limited to, nail guns (both framing and brad), impact wrenches, paint sprayers, and air ratchets.

Furthermore, it can sufficiently power tools used for inflating tires, spray painting, and sandblasting. Nevertheless, it is essential to refer to the CFM rating of the tool to ensure that it is within the operational range of the air compressor.

For instance, air tools like die grinders, angle grinders, and heavy-duty sanders often require a higher CFM. Therefore, an 8Gallon Air Compressor might not be the optimal choice for such tools, particularly for continuous use.

Always ensure to match the specifications of your tools with the capacity of your air compressor to maximize efficiency and longevity.

Can a 8 Gallon Air Compressor run a Nail Gun?

Yes, an 8Gallon Air Compressor can efficiently run a nail gun. Nail guns, including both framing and brad nailers, typically require an airflow of 0.3 to 1.5 CFM at 70 to 90 PSI. Given that an 8Gallon Air Compressor can deliver between 3.7 to 4.8 CFM at 90 PSI, it has enough capacity to power a nail gun effectively.

However, the exact requirements can vary depending on the specific model of the nail gun, so it’s always important to check the manufacturer’s specifications. If you plan on using the nail gun continuously or for prolonged periods, you might want to consider a larger compressor to avoid frequent pauses for tank refill. Always remember to adjust the air pressure according to the requirements of your nail gun for optimal performance.

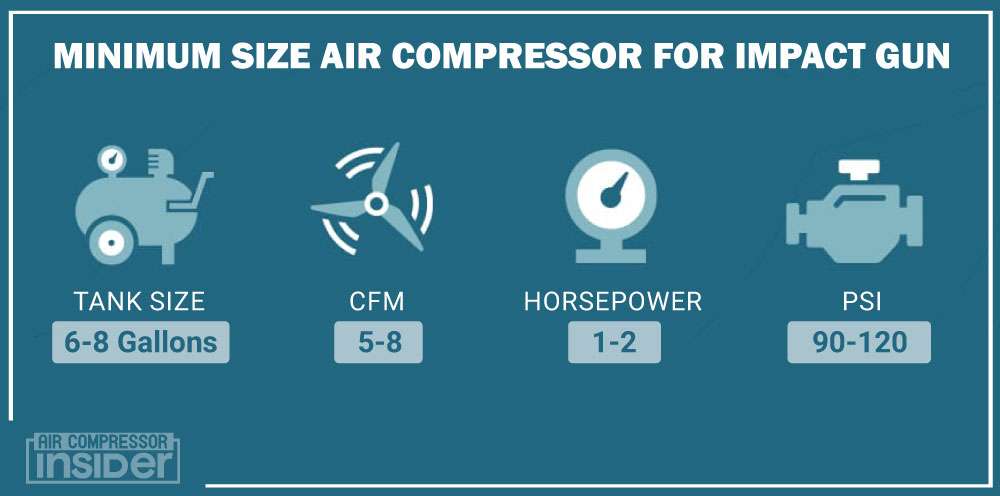

Can a 8 Gallon Air Compressor Run An Impact Wrench?

Indeed, an 8Gallon Air Compressor is capable of powering an impact wrench, but it largely depends on the specific requirements of the tool. Most 1/2 inch impact wrenches, commonly used for light to medium-duty tasks, require between 4 to 5 CFM at 90 PSI. Given the fact that an 8Gallon Air Compressor can deliver between 3.7 to 4.8 CFM at 90 PSI, it could potentially run a 1/2 inch impact wrench.

However, larger impact wrenches or those intended for heavy-duty tasks may require a higher CFM, potentially going beyond what an 8Gallon Air Compressor can provide. As always, it’s crucial to check the manufacturer’s specifications of the impact wrench to ensure compatibility with your air compressor’s output. If continuous usage or heavy-duty tasks are anticipated, a larger air compressor may be a more suitable choice.

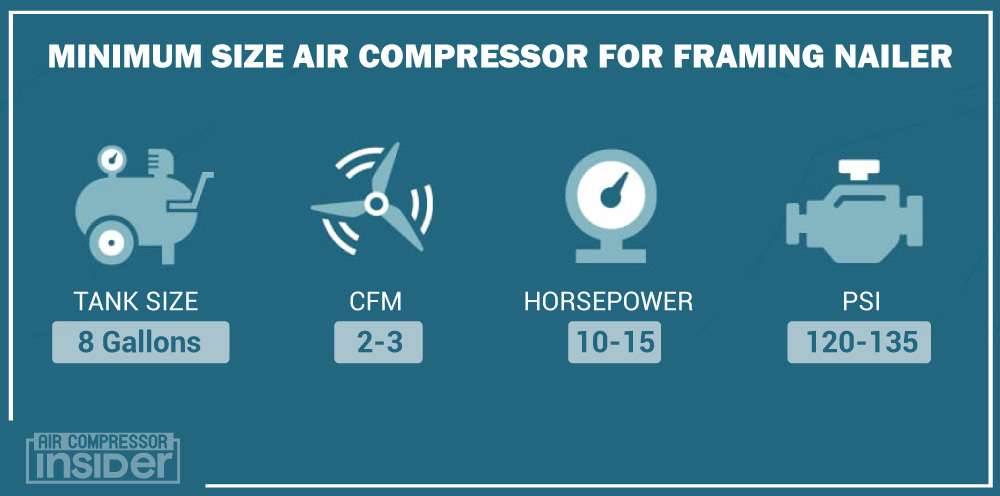

Can a 8 Gallon Air Compressor Run A Framing Nailer?

Without a doubt, an 8Gallon Air Compressor is typically capable of operating a framing nailer effectively. Framing nailers generally require an airflow of 2.2 to 2.5 CFM at 70 to 90 PSI, quite comfortably within the capacity of an 8Gallon Air Compressor which can deliver between 3.7 to 4.8 CFM at 90 PSI. This makes the compressor a suitable choice for powering these types of nailers.

However, the specific requirements can differ based on the model of the framing nailer, so it’s always recommended to check the manufacturer’s specifications. Moreover, for prolonged or continuous use of the framing nailer, a larger compressor might be necessary to minimize downtime for tank refills. As always, adjust the air pressure to match the requirements of your framing nailer for optimal performance.

Is 8 Gallon Air Compressor Good For Tires?

Yes, an 8Gallon Air Compressor is a highly practical tool for car tires. Whether it’s for bicycle tires, or even larger vehicles, this compressor has the capacity to get the job done efficiently. It can produce enough pressure (90 PSI) to inflate most tires, making it an excellent choice for both professionals in the automotive industry and individuals seeking to maintain their vehicles at home.

However, the exact time it takes to inflate a tire can vary depending on the tire’s size and the compressor’s CFM rating. Always refer to the tire’s recommended PSI and use a pressure gauge to ensure proper inflation. This will contribute to the tire’s longevity and your vehicle’s overall safety and performance.

Can You Paint With 8 Gallon Air Compressor?

Yes, you can indeed use an 8Gallon Air Compressor for paint spraying tasks. Paint sprayers usually require a compressor that can deliver between 4 to 8 CFM at 90 PSI, and an 8Gallon Air Compressor typically falls within this range. However, the exact requirements can depend on the type of paint sprayer and the extent of the painting task.

Air compressors with a larger tank capacity are often better suited for larger or continuous painting tasks as they can maintain the required CFM for a longer duration without frequent stops for tank refills. Always refer to the specifications of your paint sprayer to ensure compatibility with your air compressor. If you plan on undertaking large painting jobs or using the sprayer frequently, you might want to consider getting a larger air compressor to ensure a steady and uninterrupted supply of air.

Can You Use 8 Gallon Air Compressor To Paint A Car?

Yes, it is possible to use an 8Gallon Air Compressor for painting a car, but there are some important considerations to keep in mind. The typical air demand for auto body paint guns ranges from 4 to 14 CFM at 90 PSI, and while an 8Gallon Air Compressor often falls within this range, it may not be the optimal choice for larger or more complex paint jobs. Painting a car requires a consistent air supply, and a smaller compressor might require frequent breaks to refill the tank, which could potentially lead to an uneven paint application.

Therefore, even though an 8Gallon Air Compressor can technically be used to paint a car, for best results, a larger compressor with a higher CFM and tank capacity is usually recommended. As always, check the specifications of your paint gun to match it with the right air compressor and ensure the best possible outcome.

Will a 8 Gallon Air Compressor Run A Paint Sprayer?

Certainly, an 8Gallon Air Compressor can run a paint sprayer. Generally, paint sprayers require an air compressor that can deliver between 4 to 8 CFM at 90 PSI. An 8Gallon Air Compressor typically falls within this range, making it capable of undertaking paint spraying tasks. However, the specific requirements can vary depending on the type and model of the paint sprayer, so it’s always prudent to check the manufacturer’s specifications.

For larger or continuous paint spraying tasks, an air compressor with a greater tank capacity may be more suitable, as it can maintain the required CFM without frequent breaks for tank refills. Always ensure your air compressor aligns with the needs of your paint sprayer for the most efficient operation.

How Many PSI is 8 Gallon Air Compressor?

An 8Gallon Air Compressor typically provides an operational pressure range between 100 to 150 PSI (Pounds per Square Inch). However, the exact PSI can vary based on the specific model and manufacturer. The maximum PSI rating indicates the highest pressure that the compressor can output safely and effectively.

Always remember to check the manufacturer’s specifications for the precise PSI your air compressor can deliver. It’s crucial to match the PSI of your air compressor with the requirements of the tools you plan to use to ensure optimal performance and safety.

How Much Does 8 Gallon Air Compressor Weigh?

The weight of an 8Gallon Air Compressor can vary significantly depending on the specific model and manufacturer. Generally, you can expect an 8Gallon Air Compressor to weigh anywhere from 40 to 70 pounds. Lightweight models tend to be more portable and convenient for home use or smaller tasks, while heavier models often deliver greater power and are more suited for professional or industrial applications.

As always, it’s important to check the manufacturer’s specifications for the precise weight of your particular air compressor model. Ensure that the weight aligns with your needs, whether you require portability for on-the-go tasks or a stationary unit for demanding operations.

How Long Do 8 Gallon Air Compressors Last?

The lifespan of an 8Gallon Air Compressor can vary greatly depending on several factors including the quality of the unit, how frequently it’s used, and how well it’s maintained. Typically, a well-constructed and properly maintained air compressor can last anywhere from 10 to 15 years.

However, cheaper models or those that are heavily used without regular maintenance may need replacing after just a few years. Regular servicing, proper cleaning, and ensuring the compressor is not overworked can significantly prolong its lifespan. As with any equipment, it’s essential to follow the manufacturer’s instructions for care and maintenance to get the maximum operational life out of your 8Gallon Air Compressor.

Should I Buy 8 Gallon Air Compressor?

Absolutely, 8Gallon Air Compressors can be a valuable investment depending on your specific needs. They offer a versatile balance between power and portability, making them ideal for a range of tasks from inflating tires and running nail guns, to operating paint sprayers.

Their compact size makes them a practical choice for home use and smaller workshops where space might be a concern.

While they may not be suitable for heavy-duty industrial applications, for most DIY enthusiasts and some professionals, an 8Gallon Air Compressor provides ample capacity and performance for their needs.

As always, it’s essential to assess your specific usage requirements and match them with the capabilities of the air compressor to ensure it will meet your expectations and provide value for your investment.

How To Use 8 Gallon Air Compressor?

Using an 8Gallon Air Compressor is a straightforward process, but it’s crucial to follow the correct steps to ensure safe and efficient operation.

1. Position the Compressor:

Place your air compressor on a flat and stable surface. Make sure the unit is in a well-ventilated area and away from any flammable substances.

2. Check the Oil Level:

If your air compressor is oil-lubricated, check the oil level through the sight glass. If the oil level is low, refill it to the recommended level.

3. Connect the Air Hose:

Attach the air hose to the regulator valve of the compressor. Ensure the connection is secure to prevent air leakage.

4. Attach the Tool:

Connect your pneumatic tool to the other end of the air hose. The connection type may vary, so consult your tool’s manual if necessary.

5. Adjust the Pressure:

Turn the pressure regulator knob to match the PSI requirements of your tool. You can monitor the PSI on the compressor’s pressure gauge.

6. Power ON the Compressor:

Plug the compressor into a suitable power source, and switch it on. The compressor will start to fill its tank with air.

7. Use The Tool:

Once the pressure gauge indicates the required PSI, you can start using your tool. Monitor the pressure gauge regularly to ensure it maintains the proper PSI.

8. Power OFF the Compressor:

After completing your task, turn off the compressor and unplug it from the power source. Release any remaining air from the tank, and disconnect the air hose and tool.

Remember, always wear appropriate safety equipment when operating an air compressor and follow the manufacturer’s instructions closely. Regular maintenance will help prolong the lifespan of your 8Gallon Air Compressor and ensure its optimal performance.

Maintenance Tips For 8 Gallon Air Compressor:

Maintaining your 8Gallon Air Compressor is essential for its longevity and optimum performance. Here are some helpful troubleshooting tips:

1. Regularly Check and Change the Oil:

Maintaining your 8Gallon Air Compressor is essential for its longevity and optimum performance. Here are some helpful tips:

2. Drain Moisture from the Tank Daily:

After each use, release the air and drain any moisture from the tank. Moisture buildup can cause rusting and decrease the compressor’s life span.

3. Clean Air Filter:

The air filter prevents dust and debris from entering the compressor. A clogged filter can decrease the compressor’s efficiency, so make sure to clean it regularly and replace when necessary.

4. Inspect the Hose Regularly:

Hoses can wear out over time and can lead to air leaks. Regularly inspect them for signs of wear or damage and replace as needed.

5. Check Tightness of Fasteners:

The vibration of the compressor can loosen screws and bolts over time. Make a habit of checking the tightness of all fasteners periodically.

6. Keep the Compressor Clean:

Ensure the compressor is clean. Dust and grime can affect its performance and cause overheating.

7. Schedule Regular Servicing:

Even with regular maintenance, professional servicing is advised at least once a year to keep your compressor in top shape.

Remember; always refer to the manufacturer’s manual for specific maintenance instructions pertaining to your model.

Frequently Asked Questions

Question #1

What types of tasks is an 8Gallon Air Compressor best suited for?

An 8Gallon Air Compressor is versatile and can handle a wide range of tasks. It’s ideal for inflating tires, powering nail guns, and operating paint sprayers. Its compact size makes it a practical choice for home use and smaller workshops.

Question #2

How often do I need to service my 8Gallon Air Compressor?

For optimal performance, it’s recommended to have your air compressor professionally serviced once a year, depending on usage. Regular user maintenance, such as checking and changing oil, cleaning the air filter, and draining moisture, should still be performed regularly.

Question #3

Can an 8Gallon Air Compressor support heavy-duty industrial tasks?

Generally, 8Gallon Air Compressors are not intended for heavy-duty industrial tasks. They are better suited for home use, DIY projects, and some professional tasks.

Question #4

How do I determine the correct pressure settings for my tool?

The PSI requirements of your tool can be found in the tool’s user manual. It’s important to set the pressure regulator knob on your compressor to match these requirements.

Question #5

What risks are associated with overworking an 8Gallon Air Compressor?

Overworking an air compressor can lead to overheating, premature wear and tear, and reduced lifespan. It’s crucial to give your compressor rest intervals and not to exceed its recommended duty cycle.

Question #6

Why does my 6Gallon Air Compressor get so hot?

Check the user manual or product specifications. If it’s oil-lubricated, these sources will detail the type of oil needed and how often it should be changed.

Question #7

What happens if I don’t drain the moisture from the tank after use?

Failure to drain moisture from the tank can lead to rust formation, resulting in decreased efficiency and a shorter lifespan for your air compressor.

Question #8

What type of maintenance does an oil-free air compressor require?

Oil-free air compressors still require regular maintenance such as cleaning or replacing the air filter, checking and replacing hoses if necessary, and draining moisture from the tank.

Question #9

Why is it important to check the tightness of fasteners on an air compressor?

The vibration from the compressor’s operation can cause screws and bolts to loosen over time. Regularly checking and tightening these fasteners helps prevent potential damage or leaks.

Question #10

What safety equipment should I wear when operating an 8Gallon Air Compressor?

Safety glasses, hearing protection, and gloves are recommended when operating an air compressor. Always refer to the manufacturer’s instructions for specific safety guidelines.

Final Words:

Operating and maintaining an 8Gallon Air Compressor requires care and attention. Understanding how to use it safely and correctly, as well as scheduling regular maintenance, will help ensure your air compressor has a long life span. Remember to always refer to the manufacturer’s manual for specific instructions related to your model. Following these tips will help you get the most out of your 8Gallon Air Compressor. With the right care, it can be a powerful and reliable tool for years to come.