An 80Gallon Air Compressor is a powerful tool with numerous applications. Its large volume tank makes it a great option for sustained, high-demand tasks in both commercial and industrial settings.

Professionals often use it for heavy-duty jobs such as operating pneumatic tools, sandblasting, painting, auto repairs, and even manufacturing.

The sizable tank capacity allows the compressor to deliver a continuous supply of pressurized air, reducing the downtime needed for tank refills.

This efficiency and reliability make an 80Gallon Air Compressor a versatile and valuable piece of equipment in any context where consistent, high-pressure air supply is required.

- 80 Gallon Air Compressor – Good For Air Tools?

- Can a 80 Gallon Air Compressor run a Nail Gun?

- Can a 80 Gallon Air Compressor Run An Impact Wrench?

- Can a 80 Gallon Air Compressor Run A Framing Nailer?

- Is 80 Gallon Air Compressor Good For Tires?

- Can You Paint With 80 Gallon Air Compressor?

- Can You Use 80 Gallon Air Compressor To Paint A Car?

- Will a 80 Gallon Air Compressor Run A Paint Sprayer?

- How Many PSI is 80 Gallon Air Compressor?

- How Much Does 80 Gallon Air Compressor Weigh?

- How Long Do 80 Gallon Air Compressors Last?

- Should I Buy 80 Gallon Air Compressor?

- How To Use 80 Gallon Air Compressor?

- Maintenance Tips For 80 Gallon Air Compressor:

- Frequently Asked Questions

- Final Words:

80 Gallon Air Compressor – Good For Air Tools?

An 80Gallon Air Compressor is an excellent choice for powering a variety of air tools. The large tank capacity ensures a steady supply of compressed air, catering to the demands of high-consuming air tools such as impact wrenches, sanders, and paint sprayers.

This type of compressor is particularly suited for extensive projects or commercial applications where continuous operation is required.

However, for light-duty tasks and smaller tools, a smaller and more portable compressor might be more economical and convenient.

An 80Gallon Air Compressor can run a multitude of air tools effectively. It is ideal for heavy-duty tasks, being capable of supporting high-demand tools such as air sanders, paint sprayers, and impact wrenches.

For automotive or maintenance tasks, it can easily handle pneumatic ratchets, air hammers, and impact guns.

It’s also suitable for running HVLP spray guns, grinders, and pneumatic nail guns, making it a go-to choice for both professional and hobbyist woodworkers.

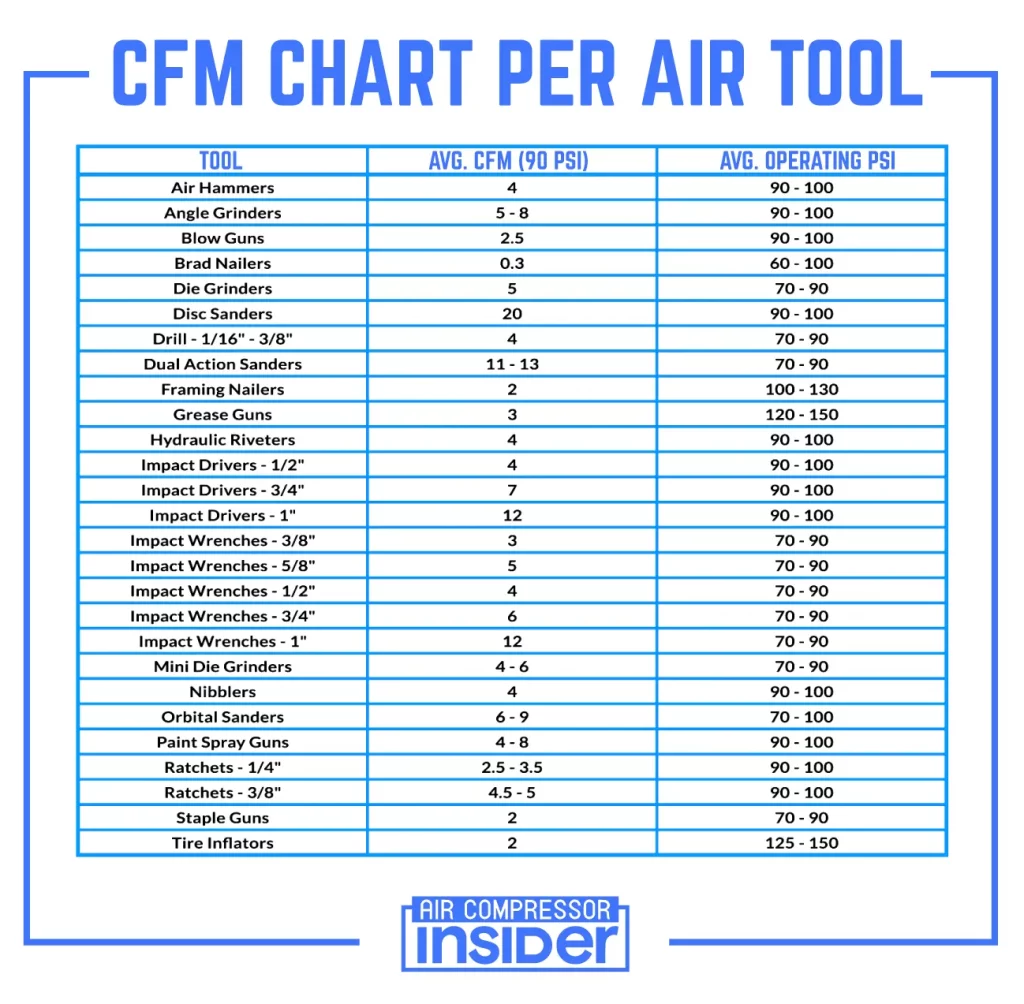

However, always ensure to check the CFM (Cubic Feet per Minute) and PSI (Pounds per Square Inch) requirements of your tools against the compressor’s specifications to ensure compatibility.

Can a 80 Gallon Air Compressor run a Nail Gun?

Absolutely, an 80Gallon Air Compressor can run a nail gun. Nail guns typically require a lower volume of air, usually between 2 to 5 cubic feet per minute (CFM), and their pressure requirements often range between 70 and 120 pounds per square inch (PSI).

An 80Gallon Air Compressor offers far above these requirements, providing ample pneumatic power for a nail gun.

However, it’s always advisable to check the manufacturer’s specifications for both the compressor and the nail gun to ensure compatibility.

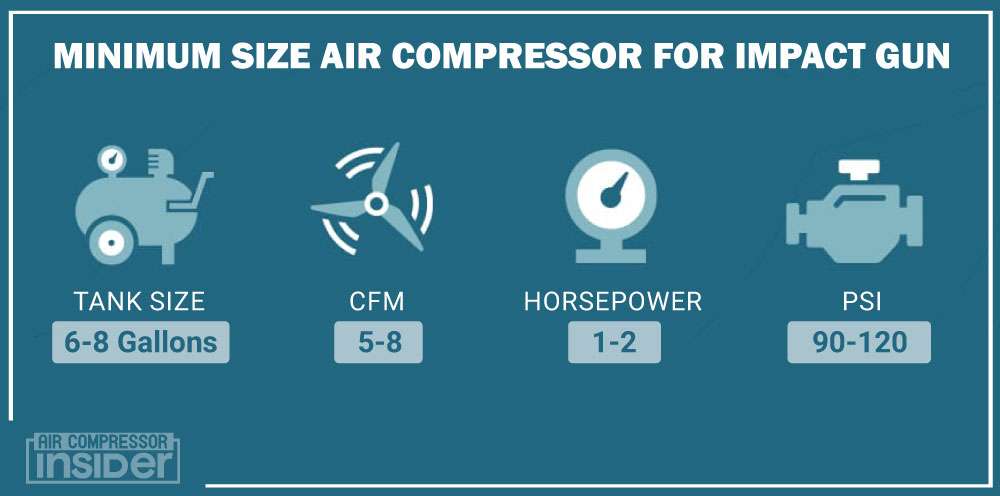

Can a 80 Gallon Air Compressor Run An Impact Wrench?

Yes, a 60 gallon air compressor can effectively run an impact wrench. The key is to ensure that the air compressor can deliver the required Cubic Feet per Minute (CFM) at the correct pressure (PSI) that the particular impact wrench demands.

Yes, an 80Gallon Air Compressor can effectively run an impact wrench. Impact wrenches typically require a relatively moderate amount of air pressure (usually between 3 to 6 CFM at 90 PSI), and an 80Gallon Air Compressor can comfortably provide this.

The larger capacity of an 80-gallon tank ensures that the compressor can maintain the necessary pressure for longer periods, allowing the impact wrench to operate continually without interruptions caused by pressure drops.

However, it’s always important to check the specific requirements of your impact wrench to ensure compatibility.

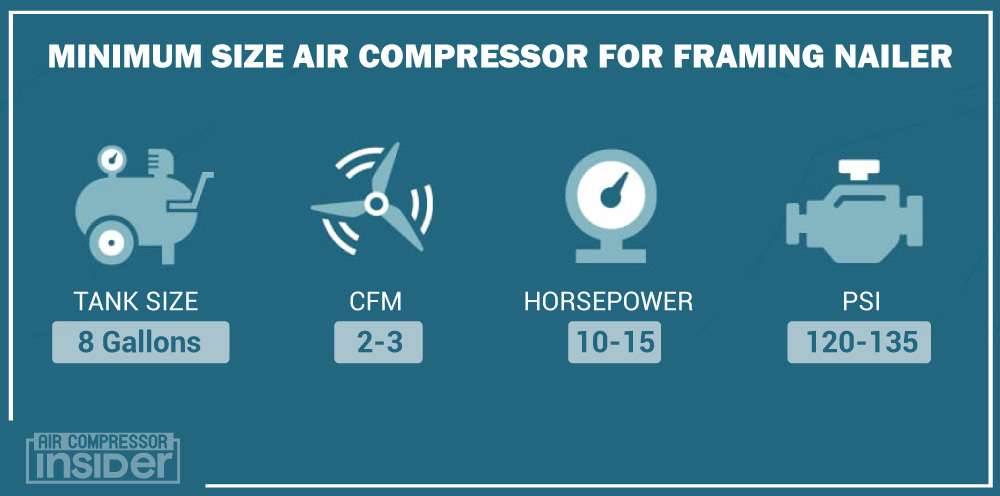

Can a 80 Gallon Air Compressor Run A Framing Nailer?

Yes, an 80 gallon air compressor can efficiently run a framing nailer. Framing nailers typically require a lower volume of air, usually 2.2 CFM (cubic feet per minute) at 90 PSI (pounds per square inch), which is well within the capacity of an 80 gallon air compressor.

Notably, the large tank size of the 80 gallon air compressor allows for longer run times before the need for the tank to refill, providing ample air supply for the operation of a framing nailer.

Is 80 Gallon Air Compressor Good For Tires?

An 80Gallon Air Compressor can be more than adequate for inflating tires. Given its large tank size, it can store a considerable amount of pressurized air.

This means it can deliver high volumes of air quickly, making it excellent for inflating not just car tires but also larger tires like those on trucks or RVs.

However, it is essential to note that such a large compressor might be overkill for simple tire inflation tasks.

Smaller, more portable air compressors can also do the job sufficient for most passenger vehicles.

A consideration of the specific use case and requirement is necessary before investing in an 80Gallon Air Compressor.

Can You Paint With 80 Gallon Air Compressor?

Yes, you can indeed paint with an 80Gallon Air Compressor. An air compressor of this size is more than capable of powering a paint sprayer for both automotive and home painting projects.

It provides a steady and continuous supply of compressed air, ensuring a smooth and uniform application of paint.

However, it’s crucial to maintain the correct air pressure and volume for your specific paint sprayer for optimal results.

Always refer to your paint sprayer’s manual for the recommended air pressure settings and adjustments.

Can You Use 80 Gallon Air Compressor To Paint A Car?

Yes, you can use an 80Gallon Air Compressor to paint a car. The size of the air compressor is particularly important when using it for painting tasks, especially for large projects like a car.

An 80Gallon Air Compressor is typically capable of delivering the consistent and sustained air pressure needed for a clean, even paint job.

However, keep in mind the type of spray gun you’re using and the PSI (Pounds per Square Inch) it requires.

As a general rule, a paint sprayer requires between 4 to 8 CFM (Cubic Feet per Minute) at 70 to 90 PSI.

An 80Gallon Air Compressor should be able to meet these requirements comfortably, making it suitable for painting a car.

Will a 80 Gallon Air Compressor Run A Paint Sprayer?

Yes, an 80Gallon Air Compressor can run a paint sprayer effectively. The typical paint sprayer requires between 4 and 8 CFM (Cubic Feet per Minute) at 70 to 90 PSI (Pounds per Square Inch).

An 80Gallon Air Compressor usually outputs considerably more than this, making it suitable for running paint sprayers.

However, the efficiency may vary depending on the specific model of both the compressor and the paint sprayer.

As a rule of thumb, always ensure to check the manufacturer’s specifications for both devices to ascertain compatibility.

How Many PSI is 80 Gallon Air Compressor?

The PSI (Pounds per Square Inch) of an 80Gallon Air Compressor can vary significantly based on the brand and model.

Generally, these compressors come with a PSI range anywhere from 100 to 175 PSI. However, the exact PSI can only be determined by referring to the manufacturer’s specifications for the specific model.

It is essential to match the PSI of your air compressor to the requirements of the tools you intend to use, such as a paint sprayer, to ensure optimal performance and safety.

How Much Does 80 Gallon Air Compressor Weigh?

The weight of an 80Gallon Air Compressor can significantly vary depending on the brand, model, and specific features.

On average, you can expect an 80Gallon Air Compressor to weigh anywhere between 400 to 800 pounds.

Industrial models with more robust features and capabilities can weigh even more.

It’s essential, therefore, to check the specifications of the particular model you’re interested in for the most accurate information.

How Long Do 80 Gallon Air Compressors Last?

The longevity of an 80Gallon Air Compressor largely depends on various factors such as its build quality, frequency of usage, and maintenance routine.

Generally, a high-quality air compressor that is well-maintained and not overused can last up to 10 to 15 years.

Regular servicing and timely replacement of worn-out parts can significantly extend the lifespan of the device.

However, it’s crucial to note that these figures can vary based on the aforementioned factors.

Always follow the manufacturer’s instructions for operation and maintenance to ensure optimal performance and longevity.

Should I Buy 80 Gallon Air Compressor?

Yes, 80Gallon Air Compressors are often worth the investment, particularly for heavy-duty or industrial applications.

These units offer a larger storage capacity, which allows for longer tool run times without the need for the compressor to kick back on.

This capacity makes them especially suitable for tools that require continuous air flow, like sanders or grinders.

Additionally, the increased storage volume often means a longer lifespan for the compressor as it doesn’t need to cycle on and off as frequently, reducing wear and tear on the motor.

However, it’s essential to assess your specific needs and usage before making a decision, as these larger units come with a higher price tag and may not be necessary for more sporadic, lighter-duty usage.

How To Use 80 Gallon Air Compressor?

Using an 80 gallon air compressor can be a straightforward process when done correctly.

1. Identify the Components:

Familiarize yourself with the primary components of the 80Gallon Air Compressor. This includes the pressure switch, gauge, safety valve, tank drain, and air outlet.

2. Check Oil Level:

Look for an oil sight glass on the side of the compressor. If the oil level is below or near the bottom marking, add more compressor oil until it reaches the top marking.

3. Connect Air Hose:

Attach the air hose to the air outlet on the compressor. Make sure it is secure before moving to the next step.

4. Set The Pressure:

Turn the pressure regulator knob to set your desired pressure. This will control the amount of air that is delivered by the compressor.

5. Turn ON the Air Compressor:

Flip the switch to the ‘on’ position. The compressor will start and begin to build pressure in the tank.

6. Wait for Tank to Fill:

Wait for the tank to fill with compressed air. Once it reaches the maximum pressure, the compressor should automatically shut off.

7. Connect Your Tool:

Attach your pneumatic tool to the other end of the air hose. Make sure it is secure before proceeding.

8. Use Your Tool:

Once the tool is connected, you can start using it. Remember to maintain proper safety measures while using the tool.

9. Turn Off the Compressor:

Once you’re done using the tool, switch off the compressor.

10. Drain the Tank:

Remove any residual moisture in the tank by opening the tank drain. This will help prevent rust and prolong the life of the compressor.

Remember, safety should be your utmost priority while using an 80Gallon Air Compressor.

Always wear safety glasses, gloves, and ear protection while operating the tool. Keep children and pets away from the work area.

Maintenance Tips For 80 Gallon Air Compressor:

When it comes to maintaining your 80Gallon Air Compressor, there are several key points to keep in mind.

1. Regular Inspection:

Regularly inspect your air compressor for any signs of wear and tear. Look for any leaks, loose fittings, or unusual noises that might indicate an issue.

2. Clean Air Filter:

A clean air filter is essential for the efficient operation of your air compressor. Replace or clean it regularly to prevent dust and debris from entering the system.

3. Check the Oil Level:

Regularly check the oil level if your compressor is oil-lubricated. Maintain the oil at the recommended level and change it according to the manufacturer’s instructions.

4. Inspect Belts:

Examine the compressor’s belts periodically for any signs of wear or damage. If they appear cracked or frayed, consider replacing them promptly.

5. Drain Moisture from the Tanks:

Water can accumulate in the tanks due to condensation. Make it a habit to drain the tanks after each use.

6. Check and Tighten Bolts:

The bolts can loosen over time due to the compressor’s vibration. Regularly check and tighten them to ensure the machine’s stability.

7. Keep the Compressor Clean:

Wipe down the compressor regularly to prevent dust and dirt accumulation, which can affect its performance.

8. Maintain Optimal Pressure:

Always maintain the compressor within the manufacturer’s recommended pressure range to avoid unnecessary strain on the system.

9. Proper Storage:

Store the compressor in a clean, dry, and well-ventilated area to protect it from environmental damage.

10. Scheduled Professional Maintenance:

Lastly, schedule regular professional maintenance to ensure your compressor’s longevity and optimal performance. While DIY maintenance can help, a professional can identify and fix issues that might be easily overlooked.

Frequently Asked Questions

Question #1

What is an 80Gallon Air Compressor used for?

An 80Gallon Air Compressor is generally used for heavy-duty industrial tasks such as operating pneumatic tools, sandblasting, painting, or running multiple air tools simultaneously due to its large tank capacity.

Question #2

How much PSI does an 80Gallon Air Compressor provide?

The PSI (pounds per square inch) provided by an 80Gallon Air Compressor can vary depending on the model, but most offer between 135 to 175 PSI.

Question #3

What kind of power source does an 80Gallon Air Compressor need?

Most 80Gallon Air Compressors use a standard 240-volt electrical outlet, but it’s always advisable to check the specific requirements of your particular model.

Question #4

Are there any special maintenance requirements for an 80Gallon Air Compressor?

Like all air compressors, the 80-gallon variety requires regular maintenance. This includes draining the tank to remove condensation, changing the oil (if it’s an oil-lubricated model), and checking and replacing the air filter as needed.

Question #5

What is the expected lifespan of an 80Gallon Air Compressor?

With proper maintenance, an 80Gallon Air Compressor can last for many years. The actual lifespan will depend on the quality of the compressor and how frequently it’s used.

Question #6

Is an 80Gallon Air Compressor noisy?

While an 80Gallon Air Compressor can produce noise, many models are equipped with noise-reducing features. It’s always a good idea to check the decibel rating before purchasing.

Question #7

How much does an 80Gallon Air Compressor weigh?

The weight of an 80Gallon Air Compressor can vary greatly depending on the specific model and construction materials. However, it’s safe to say that they are generally quite heavy and may require multiple people or equipment to move.

Question #8

What are the dimensions of an 80Gallon Air Compressor?

The dimensions of an 80Gallon Air Compressor can vary, but they are generally around 35 inches in width, 80 inches in height, and 32 inches in depth.

Question #9

Can I use an 80Gallon Air Compressor at home?

While an 80Gallon Air Compressor can certainly be used at home, its size and power make it more suitable for industrial or commercial applications.

Question #10

Are there any safety precautions when using an 80Gallon Air Compressor?

Yes, safety precautions must be taken when using an 80Gallon Air Compressor. These include wearing protective gear, keeping the area around the compressor clear, and following all manufacturer’s instructions and safety guidelines.

Final Words:

In conclusion, owning and operating an 80Gallon Air Compressor requires understanding, preparation, and a commitment to regular maintenance.

These substantial machines can deliver the power needed for industrial tasks, making them a valuable addition to any commercial operation.

However, proper safety measures should be observed at all times due to the inherent risks associated with high-pressure equipment.

Lastly, by conducting regular inspections, keeping the compressor clean and well-maintained, and enlisting professional help for scheduled maintenance, you can ensure that your air compressor performs optimally and lasts for many years.