What is a Single Stage Air Compressor – Detailed Guide 2025

Air compressors are of two types: single stage and two stage. In this article, we will discuss in detail what is a single stage air compressor.

What is a Single Stage Air Compressor?

A single stage air compressor compresses the air one time. Single-stage air compressors are cheaper, and are ideal for light-duty air-powered tools that have to be used occasionally. Single stage air compressors use one piston, located in the only cylinder it has. This is why the structure and body of single stage air compressor is set according to its functionality. Single stage air compressors are used for running light-pressure pneumatic tools.

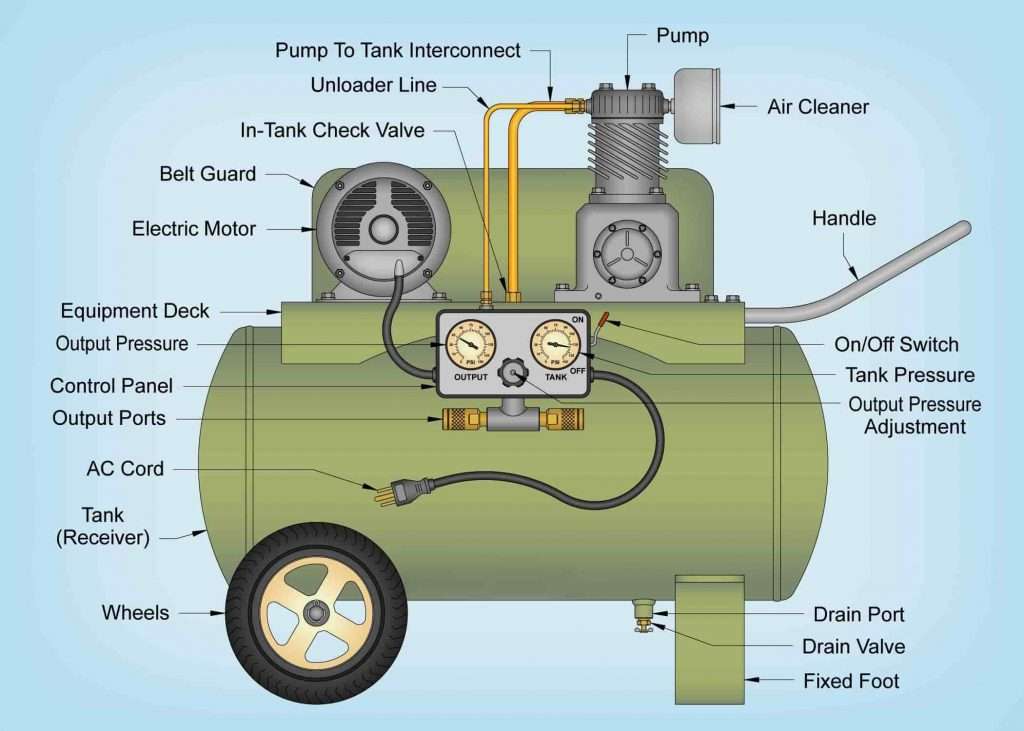

Main Components of Single Stage Air Compressor

Before discussing how a single stage air compressor works, let’s first discuss some of the main components of a single stage air compressor.

The main components of a single stage compressor are listed below:

- Inlet Valve / Suction Valve

- Cylinders

- Piston

- Piston Rings

- Crankshaft

- Connecting Rod

Inlet Valve:

Inlet Valve (also called suction valve) is present on the piston cylinder and is used to suck the air inside the air compressor cylinder from an external source.

Cylinder:

Cylinder is the most important component in a single stage air compressor. Usually, this cylinder is made up of cast iron or steel. The single stage air compressor has one cylinder that contains the gas that is to be compressed.

Piston:

Single stage air compressors have one piston, which is used for the compression of air. Single stage air compressor’s piston moves upward and backward in the cylinder to compress the air. When the piston moves backward, it sucks the air. And when moves forward, it compress the air.

Piston Rings:

Single stage air compressor’s piston has rings that help in keeping the compressed air on top of the piston. When the piston moves upward and backward in the cylinder, the piston rings come in between the piston and cylinder walls.

Crankshaft:

Single stage air compressor has two shafts: crankshaft and motor shaft. Crankshaft is the one which plays the most vital role. It is directly connected with the electric motor, and is used to rotate the piston for air compression.

Connecting Rod:

Connecting rod is also an important component in an air compressor, which connects the piston and the crankshaft, and also controls the movement of piston.

Connecting rod is made up of either a ductile iron rod, or forged steel, depending on the air compressor’s power. One side of the connecting rod is connected with the piston with the help of piston pin. While the other side is connected with the crankshaft with the help of a connecting cap rod.

Outlet Valve:

The outlet valve (also called delivery valve) is present inside the cylinder and takes the compressed air out after the compression process is completed.

What Is Better Single Stage Or Two Stage Air Compressor?

Both single stage and 2 stage air compressors have some merits and demerits, depending upon the usage and requirements.

Single-stage air compressors are ideal for light-duty air-powered tools that occasionally have to be used. Single stage air compressors are also handy for painting cars.

Two-stage air compressors can handle large pressure requirements such as 100 PSIG, unlike single-stage air compressors.

Two-stage air compressors are more reliable and efficient than single-stage air compressors.

How Does A Single Stage Air Compressor Work?

Single stage air compressor is operated by a piston and a pressure measuring valve. It has one cylinder, so all the air compression takes place in that only cylinder. The inlet and outlet valves are connected with the cylinder.

Single stage air compressor has a crankshaft and connecting rod that controls the reciprocation motion of the piston inside the compression cylinder.

Inlet Valve (also called suction valve) is present on the piston cylinder and is used to suck the air inside the air compressor cylinder from an external source. Whereas, the outlet valve (also called delivery valve) is present inside the cylinder and takes the compressed air out after the compression process is completed.

In single stage air compressor, the volume of air becomes zero when the piston reaches the TDC (Top Dead Centre) and the cylinder’s internal pressure becomes lower than the outside atmospheric pressure. This difference in pressure opens the suction stroke and the suction process starts. The suction valve starts sucking the air inside the air compressor cylinder.

When the air compressor piston reaches the BDC (Bottom Dead Centre), it starts to move upward and starts compressing the air.

This compression process continues until the cylinder’s internal pressure gets higher than the external air pressure. As soon as it happens, the inlet valve (suction valve) closes.

Inside the cylinder, the piston moves at a very high speed and continuously puts pressure on the cylinder. The air compressor’s cylinder is designed with a slight curve at the top; otherwise this continuous pressure reduces the life of air compressor.

This air compression process continues until the cylinder’s internal pressure gets higher than the external air pressure. As soon as it happens, the outlet valve (delivery valve) opens up.

Outlet valve is connected between the cylinder and the storage tank.

As soon as the outlet valve is opened, the compressed air is released to the storage tank. The storage tank keeps on filling, and then this compressed air is transferred to the receiver or any pneumatic tool from the storage tank with the help of a hose.

How To Connect Hose To Single Stage Air Compressor

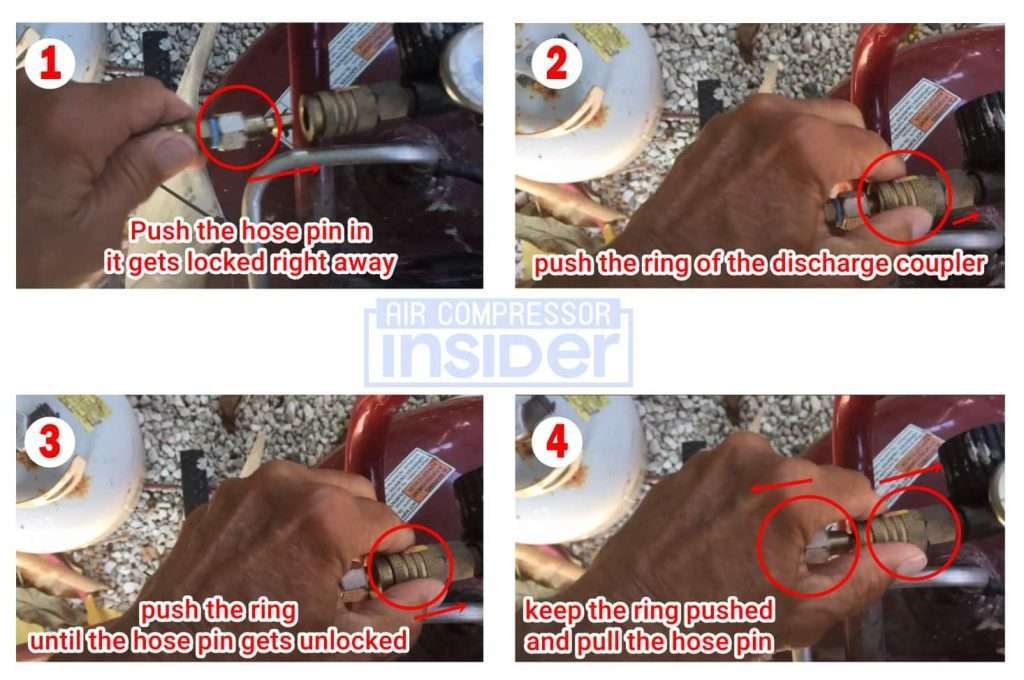

Connecting a hose to single stage air compressor is pretty simple.

To keep it simple, we assume that both ends of the hose already have fittings attached, and you only want to know how to connect a hose to single stage air compressor.

Simple, here is how we’ll do it. All you get to do is push the hose pin in, it gets locked right away, and it will be connected with the air compressor.

And when you want to unplug the hose, push the ring of the discharge coupler on the compressor’s end, and pull the hose connector pin from the compressor’s discharge coupler.

Now leave the compressor’s ring back to its position. (as shown in the image below)

What Are The Disadvantages Of Single Stage Reciprocating Compressor?

Single-stage air compressors have some limitations as compared to two stage air compressors.

- Single-stage air compressors operate at a fast speed therefore increases the bearing load which decreases the compressor’s life.

- Single-stage air compressors are less reliable as compared to two-stage air compressors.

- Single-stage air compressors have one cylinder, therefore the air pressure and work efficiency is less than two-stage air compressors.

- Single stage air compressors require more frequent maintenance as compared to two-stage air compressors.

- Single-stage air compressors consume up to 12% more energy as compared to two-stage air compressors.

- Single-stage air compressors are not efficient for commercial production or for large manufacturing operations.

What Is Better Single Stage Or Two Stage?

Two-stage air compressors are recommended for industrial and commercial purposes such as manufacturing, house painting, sandblasting etc. It has more cylinder stages and pressure, increasing work efficiency by handling more air-powered tools with a faster recovery time.

“In larger installations, dual compression is better, but for smaller operations, these compressors may not be as suitable, as the same savings are not translatable.”

– Caps.com.au

How Hot Does A Single Stage Air Compressor Get?

The maximum operating temperature for an air compressor in the discharge line is between 185℉ and 190℉. If the temperature goes beyond this range, it can cause your air compressor to shut down.

What Causes An Air Compressor To Overheat?

The most common reason for overheating an air compressor is the rise in temperature and humidity in the air.

Some other factors that can overheat an air compressor are low-level oil, dirty radiator, low ventilation, and some mechanical issues that can cause your air compressor to overheat.

How To Prevent An Air Compressor From Overheating

Like all other tools and equipment, air compressors also need routine maintenance.

Single stage air compressors require more frequent maintenance than two stage air compressors. So you have to pay special attention before summer kicks off, and high temperature causes your air compressor to overheat.

Any negligence in this regard can cause your air compressor to shut down and give you unexpected maintenance expenses.

If you use your air compressors very often, installing temperature and humidity sensors at critical spots of your workplace will be a wise investment. These sensors will help you keep an eye on the surrounding temperature.

Single Stage Air Compressor Pricing

Single stage air compressors are less expensive than two stage air compressors. They have wide range of pricing depending upon the power and performance.

Small 2–5 HP single stage air compressors starts from $500 and goes up to $1500. And higher 200 HP models goes up to $50,000.

If you want to use air compressor occasionally and for light-duty tools, such as for kitchen equipment or for personal use in the garage, then we always recommend you to purchase a single stage air compressor and save substantial amount of money.

Single Stage Air Compressor

| Single Stage Compressor | |

| Air Compression | One time |

| Air Pressure | Less air pressure |

| Recommended Usage | For light-duty air-powered tools for personal use in garage or kitchen |

| Reliability | Reliable only if used on low scale |

| Efficiency | Efficient only if used on low scale |

| Cylinder Stages | Single cylinder stage |

| Recovery Time | Low recovery time |

| CFM (cubic feet of air moved per minute) | Low CFM |

| Pricing | Reasonable price |

| Maintenance | Requires more and frequent maintenance |

| Energy Consumption | Consumes much more energy |

| Intercooler | No intercooler |

Frequently Asked Questions

Question #1

Where can you use a single stage air compressor?

Single-stage air compressors are ideal for light-duty air-powered tools that occasionally have to be used. Such as inflating a tire, operating a nail gun or impact wrench, refilling a Co2 tank, HPA tank, or a paintball tank and much more. You can also blow out your sprinkler system with an air compressor with a single stage air compressor!

Question #2

What are the drawbacks in single stage compression?

Single-stage air compressors have some drawbacks as well.

- Single-stage air compressors operate at a fast speed therefore increases the bearing load which results in decreasing the compressor life.

- Single-stage air compressors are less reliable as compared to two-stage air compressors.

- Single-stage air compressors have one cylinder, therefore the air pressure and work efficiency is less than two-stage air compressors.

- Single stage air compressors require more frequent maintenance as compared to two-stage air compressors.

- Single-stage air compressors consume up to 12% more energy as compared to two-stage air compressors. – Single-stage air compressors are not efficient for commercial production or for large manufacturing operations.

Question #3

Why we cannot use single stage air compressor?

You can use single stage air compressor for running light-duty air-powered tools at your home or garage. Whereas, two-stage air compressors can handle large pressure requirements such as 100 PSIG and more.

Question #4

Is a two stage air compressor better than a single stage?

Yes, two stage air compressors are better than a single stage air compressor.

Two-stage air compressors are recommended for industrial and commercial purposes such as manufacturing, auto repairing, etc. This is because it has more cylinder stages and pressure, increasing work efficiency by handling more air-powered tools with a faster recovery time.

Question #5

What is the difference between single stage and single phase on an air compressor?

Single stage and single phase on an air compressor is similar. Therefore, some people call it a single-stage air compressor, while some call it a single-phase air compressor.

Question #6

What is the difference between a single stage and two stage air compressor?

The difference between a single stage vs two stage air compressor is the number of times the air gets compressed.

In a single stage, the air is compressed one time. Now you will ask, what is a two stage air compressor? In the two stage, the air is compressed two times. Therefore, two stage air compressors are more reliable and efficient than single stage air compressors.

Conclusion:

Now, as we have discussed what is a single stage air compressor, so to summarize we can say, single-stage air compressors are cheaper, and are reliable and efficient for light-duty air-powered tools for your home or garage