Air compressors are of two types: single stage and two stage. Two stage air compressors have many additional benefits and advantages, therefore in this article, we will discuss in detail what is a two stage air compressor.

- What is a Two Stage Air Compressor

- Main Components of Two Stage Air Compressor

- How Does A Two Stage Air Compressor Work?

- What Are The Advantages Of Two Stage Air Compressor?

- Two Stage Air Compressors Are Better Than A Single Stage

- Two Stage Air Compressor Are More Reliable

- How Hot Does A Two Stage Air Compressor Get?

- What Causes An Air Compressor To Overheat?

- How To Prevent An Air Compressor From Overheating

- Two Stage Air Compressor Pricing

- Do Two Stage Air Compressors Save Energy?

- Two Stage Air Compressor Pump

What is a Two Stage Air Compressor

A two stage air compressor compresses the air two times to double the pressure, resulting in double efficiency and power. In addition, two stage air compressors are more reliable and efficient, build less moisture in the tank, and require less maintenance.

Two stage air compressors use two pistons located in two separate cylinders. One piston compresses the air, while the other piston transfers the compressed air from the cylinder to the other.

Two stage air compressors are used for running high-pressure machinery. These are a bit expensive, thats why do always do proper research to make sure you purchase the best 2 stage air compressors.

Large air compressors ranging from 5 HP to 50,000 HP are used in large industrial plants throughout production and maintenance operations.

The running cost of such large units is many times more than the actual cost. Therefore, large two stage air compressors are installed. So air compression is done in more than one stage to reduce running cost, and between each stage, the intercooler is provided, which allows air to cool down in the tank for a more extended period before it is required to be used.

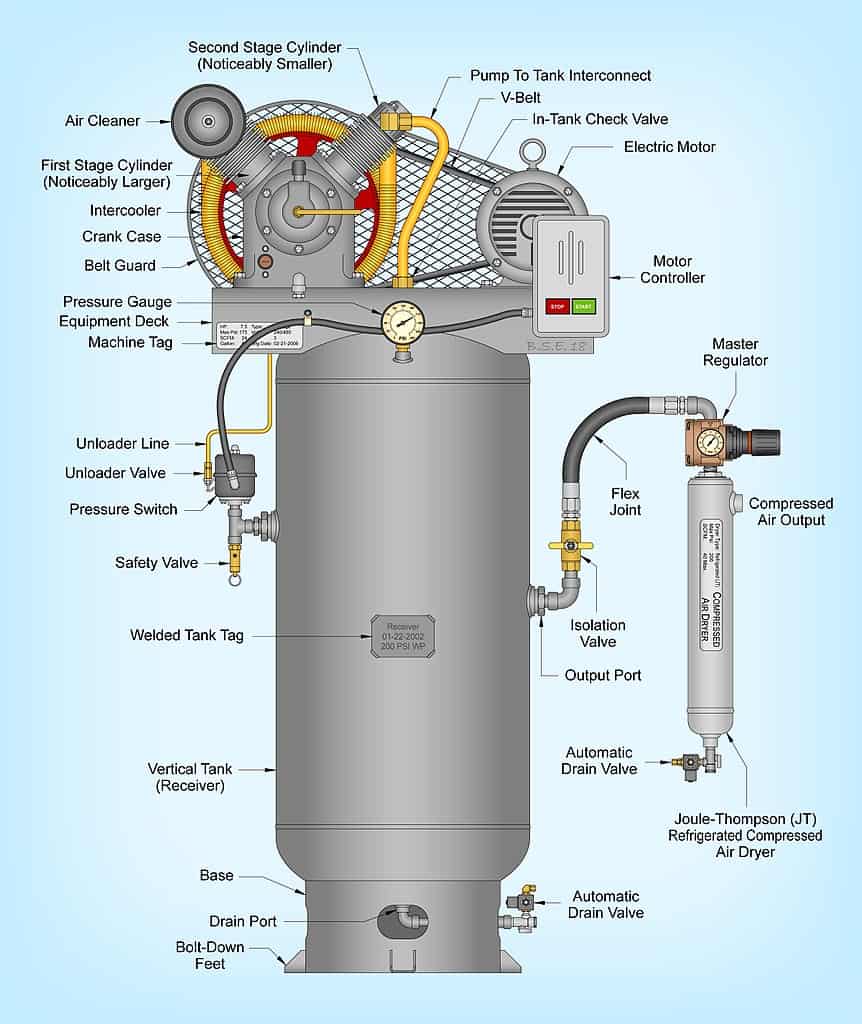

Main Components of Two Stage Air Compressor

Before discussing how a two stage air compressor works, let’s first discuss some of the main components of a two stage air compressor.

The main components of a two stage compressor are listed below:

- Inlet Valve / Suction Valve

- Intercooler

- Piston

- Low-Pressure Cylinder(LPC)

- High-Pressure Cylinder(HCP)

- Outlet Valve

Inlet Valve:

Inlet Valve (also called suction valve) is present on the piston cylinder and is used to suck the air inside the air compressor cylinder from an external source.

Intercooler:

The air becomes too hot after the first stage of compression. So, a cooling pipe is placed between Low-Pressure Cylinder (LPC) and High-Pressure Cylinder (HPC), an intercooler.

An intercooler’s primary function is to cool down the compressed air before reaching the second cylinder. This cooling process is done by air or oil, or water.

Piston:

Two stage air compressors have two pistons. One of which is connected with a crankshaft via a connecting rod. The crankshaft rotates along with the connecting piston, which moves the piston forward and backward.

Low-Pressure Cylinder (LPC):

Due to the low air pressure, this cylinder is named Low-Pressure Cylinder (LPC). The LPC has high dimensions and compresses the air up to 90 PSI.

High-Pressure Cylinder (HPC):

Due to the high air pressure, up to 175PSI, this cylinder is named a High-Pressure Cylinder (LPC). The LPC sends the compressed air again for second-stage compression.

Outlet Valve:

The outlet valve is present inside the cylinder and takes the compressed air out after the compression process is completed.

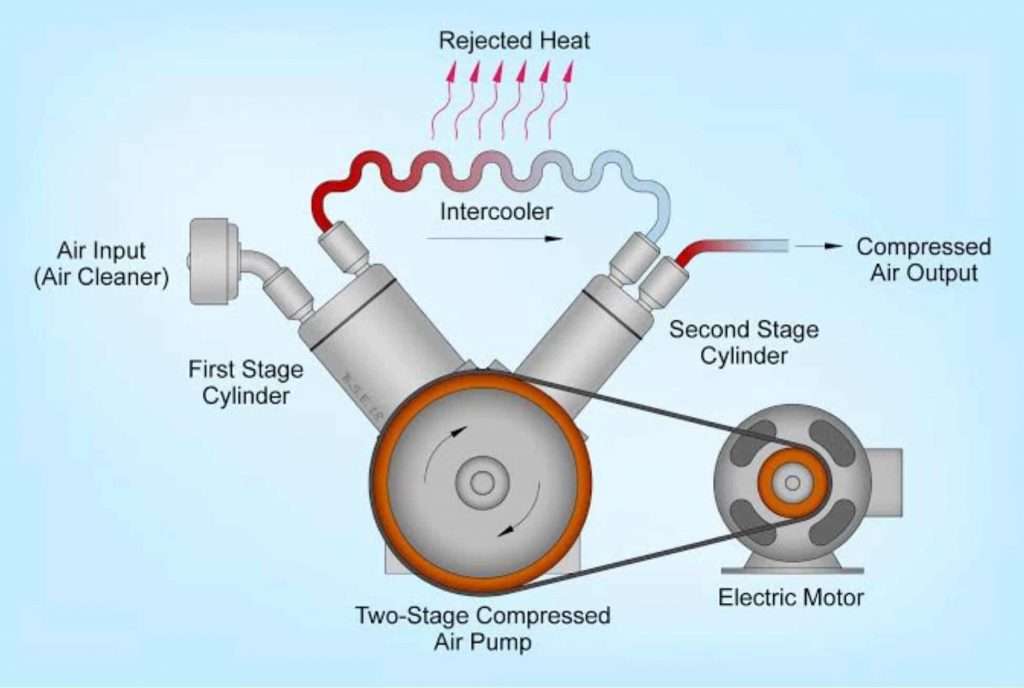

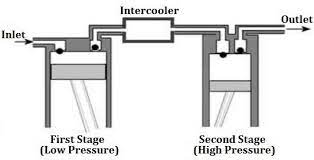

How Does A Two Stage Air Compressor Work?

Two-stage air compressors feature two cylinders, each of a different diameter. Between both compression stages, an intercooler cools down the compressed air before reaching the second cylinder.

Two stage air compressor diagram

This cooling down of compressed air eases the further compression, resulting in energy saving of 10% to 12% (as shown in the image below).

Air is then forced into an additional chamber where it is pressurized for industrial usage.

Two stage air compressor has two pistons. One of which is connected with a crankshaft via a connecting rod. The crankshaft rotates along with the connecting piston, which moves the piston forward and backward.

What Are The Advantages Of Two Stage Air Compressor?

Two-stage air compressors have many advantages as compared to single-stage air compressor.

- Two-stage air compressors operate at a slow speed, therefore, splitting the pressure ratio into two stages, reducing the bearing load and significantly extending the compressor life.

- Two-stage air compressors are more reliable as compared to single-stage air compressors.

- Two-stage air compressors double the air pressure, increasing work efficiency and being much more reliable than single-stage air compressors.

- Two stage air compressors require less maintenance, have less moisture buildup in their tank, and also allow air to cool down in the tank for a more extended period before it is required to be used.

- Two-stage air compressors save energy up to 12%.

- Two-stage air compressors can increase commercial production efficiency and reduce waste in large manufacturing operations.

Two Stage Air Compressors Are Better Than A Single Stage

Two-stage air compressors are recommended for industrial and commercial purposes such as manufacturing, auto repairing, etc. It has more cylinder stages and pressure, increasing work efficiency by handling more air-powered tools with a faster recovery time.

“In larger installations, dual compression is better, but for smaller operations, these compressors may not be as suitable, as the same savings are not translatable.”

– Caps.com.au

Two Stage Air Compressor Are More Reliable

The reliability of an air compressor depends upon the usage and maintenance of your air compressor.

Two-stage air compressors are reliable for factory or commercial use because it has the required CFM (cubic feet of air moved per minute). In addition, it can handle heavy-duty air-powered tools for professional services, such as painting and sanding, which requires as much as 100 PSIG.

How Hot Does A Two Stage Air Compressor Get?

The maximum operating temperature for an air compressor in the discharge line is between 185℉ and 190℉.

If the temperature goes beyond this range, it can cause your air compressor to shut down.

What Causes An Air Compressor To Overheat?

The most common reason for overheating an air compressor is the rise in temperature and humidity in the air.

Some other factors that can overheat an air compressor are low-level oil, dirty radiator, low ventilation, and some mechanical issues that can cause your air compressor to overheat.

How To Prevent An Air Compressor From Overheating

Like all other tools and equipment, air compressors also need routine maintenance.

Two stage air compressors require less maintenance than single stage air compressors. Still, you have to pay special attention before summer kicks off, and high temperature causes your air compressor to overheat.

Any negligence in this regard can cause your air compressor to shut down and give you unexpected maintenance expenses.

If you use your air compressors very often, installing temperature and humidity sensors at critical spots of your workplace will be a wise investment. These sensors will help you keep an eye on the surrounding temperature.

Two Stage Air Compressor Pricing

Two stage air compressors are more expensive than single stage air compressors.

Two stage small air compressors for residential usage start from $400-$500 and go up to $1400-$1500.

Professional models of two-stage air compressors for commercial purposes starting from 5 HP for $1500 up to 200 HP for $50,000.

The primary reason for a higher price is that two-stage air compressors have more parts.

Do Two Stage Air Compressors Save Energy?

Two stage air compressors have smaller parts, which requires less maintenance than single stage air compressors. As a result, it has less moisture buildup in its tank and also allows air to cool down in the tank for a more extended period before it is required to be used.

Two stage air compressors also reduce production costs because you can use multiple pneumatic tools together.

Thus, for commercial use, your initial investment in a two-stage air compressor could save you money over time.

Many large-scale manufacturers confirm the substantial savings with two-stage air compressors, which provide an energy saving of 10% to 12%.

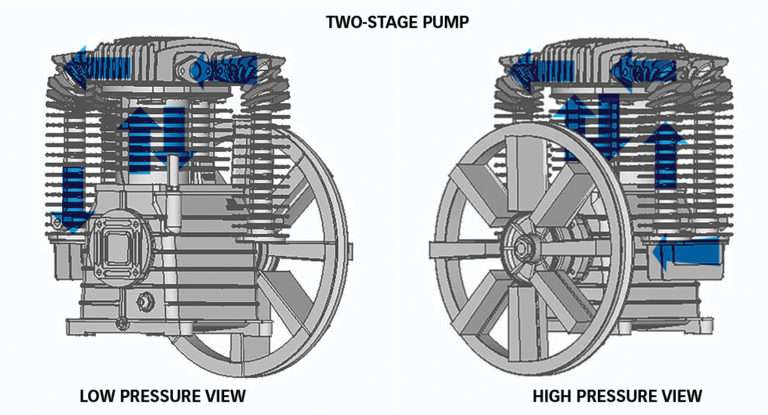

Two Stage Air Compressor Pump

As discussed above, the primary difference between Single Stage vs Two Stage Air Compressor is the number of times the air gets compressed.

And when we talk about air compression, it’s all about the pump. Because the number of times the air will be compressed is determined by the configuration of the air compressor pump, which comes in different varieties, sizes, shapes, and piston configurations.

One stage air compressor pumps compress the air once, whereas two stage air compressor pumps compress the air two times.

Two stage air compressor pumps have two pistons. One is a high-pressure piston, small in size, whereas the other is a low-pressure larger piston.

Two stage air compressors are also handy for painting cars.

Two Stage Air Compressor

| Two Stage Compressor | |

| Air Compression | Two times |

| Air Pressure | Much more air pressure as compared to single stage |

| Recommended Usage | For professional and commercial use on large scale as much as 100 PSIG |

| Reliability | Much more reliable as compared to single stage air compressor |

| Efficiency | Much more efficient as compare to single stage air compressor |

| Cylinder Stages | Multiple cylinders and stages |

| Recovery Time | Faster recovery time |

| CFM (cubic feet of air moved per minute) | High CFM |

| Pricing | Much more expensive |

| Maintenance | Requires less maintenance |

| Energy Consumption | Reduces energy consumption up to 12% |

| Intercooler | Intercooler is included which allows air to cool down |

Frequently Asked Questions

Question #1

What is the advantage of a two stage air compressor?

Two-stage air compressors have many advantages as compared to single-stage air compressors.

– Two-stage air compressors operate at a slow speed, therefore, splitting the pressure ratio into two stages, reducing the bearing load and significantly extending the compressor life.

– Two-stage air compressors are more reliable as compared to single-stage air compressors.

– Two-stage air compressors double the air pressure, increasing work efficiency and being much more reliable than single-stage air compressors.

– Two stage air compressors require less maintenance, have less moisture buildup in their tank, and also allow air to cool down in the tank for a more extended period before it is required to be used.

– Two-stage air compressors save energy up to 12%.

– Two-stage air compressors can increase commercial production efficiency and reduce waste in large manufacturing operations.

Question #2

Is a two stage air compressor better than a single stage?

Yes, two stage air compressors are better than a single stage air compressor.

Two-stage air compressors are recommended for industrial and commercial purposes such as manufacturing, auto repairing, etc. This is because it has more cylinder stages and pressure, increasing work efficiency by handling more air-powered tools with a faster recovery time.

Question #3

What is the purpose of a 2 stage compressor?

The primary purpose of a two-stage air compressor is to compress the air two times to double the pressure, resulting in double efficiency and power. Two stage air compressors are more reliable and efficient, build less moisture in the tank and require less maintenance.

Question #4

How do I know if my air compressor is two stage?

You can have an idea if it’s a two stage air compressor just by looking at it.

If it has two cylinders mounted side by side, and one side is bigger than the other, it clues that it is a two stage air compressor.

You can also know it by monitoring the working of an air compressor. For example, if the air is sucked in by one piston and then directly sent to the tank, it is a single stage air compressor.

Whereas, if the air is sucked in by one piston and then sent to another piston through an inter-connecting/ intercooler pipe, it is a two stage air compressor.

Question #5

Is a two-stage compressor worth it?

Two stage air compressors reduce production costs because you can use multiple pneumatic tools together.

Many large-scale manufacturers confirm the substantial savings with two-stage air compressors, which provide an energy saving of 10% to 12%. Thus, for commercial use, your initial investment in a two-stage air compressor could save you money over time.

Question #6

What is the difference between two stage and two phase on an air compressor?

Two stage and two phases on an air compressor are similar. Therefore, some people call it a two-stage air compressor, while some call it a two-phase air compressor.

Question #7

What is the difference between a single stage and two stage air compressor?

The difference between a single stage vs two stage air compressor is the number of times the air gets compressed.

In a single stage, the air is compressed one time. Now you will ask, what is a two stage air compressor? In the two stage, the air is compressed two times. Therefore, two stage air compressors are more reliable and efficient than single stage air compressors.

Conclusion:

Now, as we have discussed what is a two stage air compressor, so to summarize we can say, two-stage air compressors are expensive but are reliable and efficient for heavy-duty and non-stop use.