Many people are in the hunt for a reliable and well-suited air compressor for air hammer, because of the power, convenience and versatility that an air hammer offers. If you’ve ever navigated the aisles of your local hardware store, then you know there are many different types and sizes of air compressors.

But how do you determine what size air compressor for air hammer is right for your needs? In this article, we’ll cover just how important specific size matters when it comes to selecting an appropriately sized air compressor for running your air hammer. So lets get started!

What Size Air Compressor For Air Hammer

For an air hammer, you’ll need an air compressor with a CFM rating of at least 5 and a PSI rating around 90. HP should be 15-20, and the tank size should be around 6 gallons or higher.

What Is An Air Hammer?

An air hammer is a specialized pneumatic tool that uses compressed air from an air compressor to generate power. It’s designed for chiseling and shaping metal, concrete, masonry and other materials with rapid, powerful blows. The size of the hammer cylinder determines how much force it can deliver per blow; larger cylinders create more powerful blows.

Types of Air Hammers:

There are three main types of air hammers: small, medium, and large.

1- Small Air Hammers

2- Medium-Sized Air Hammers

3- Large Air Hammers

1- Small Air Hammers:

Small air hammers can generally handle the most common applications around the home such as light chipping and riveting.

2- Medium-Sized Air Hammers:

Medium-sized hammers have more power for larger projects like smashing concrete or heavier metalwork.

3- Large Air Hammers:

Large air hammers typically require a large air compressor, and can handle the most demanding chiseling applications like cutting sheet metal.

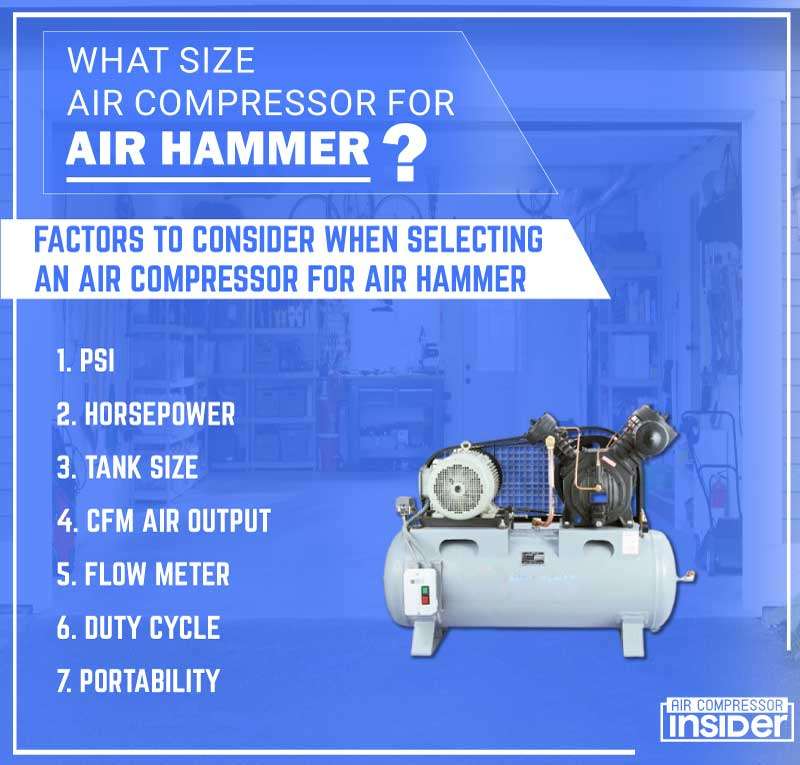

7 Important Factors to Consider When Selecting an Air Compressor for Air Hammer:

When selecting an air compressor for air hammer, it’s important to familiarize yourself with the following key specs:

1. PSI Rate:

PSI stands for “pounds per square inch” and is a measure of the amount of pressure that an air compressor can generate. Air hammers require high-pressure compressors which can generate at least 90 PSI.

2. Horsepower:

The horsepower (HP) of an air compressor dictates the amount of air that can be produced per minute, and thus how quickly the hammer can work. Generally, the more HP your compressor has, the faster it will be able to deliver a consistent stream of air to your air hammer.

3. Tank Size:

The size of an air compressor tank plays a role in determining its overall power output as well as how often you’ll need to stop work to let it recharge. When selecting an air compressor for your project, make sure that the tank is large enough for all the applications you anticipate needing it for.

4. CFM Air Output:

CFM stands for “Cubic Feet per Minute” and is a measure of how much air the compressor can move per minute. Generally, it’s best to go with a compressor that has at least 5 CFM in order to ensure you have enough power for your tasks.

5. Flow Meter:

Flow meters are used to measure the amount of air being used by an air hammer so you know when it needs more air or if it’s using too much. It also helps regulate the pressure so you don’t overdo it and damage your tools or work piece.

6. Duty Cycle:

This is simply the percentage of time that an air compressor can run before needing a break to cool down and recharge its tank. A duty cycle rating of 50% means that an air compressor should be able to run for up to 30 minutes every hour.

7. Portability:

If you plan on moving your air compressor around, then portability is something to consider when selecting the right size one for your needs. A larger compressor will be heavier and more difficult to move than a smaller one, so make sure to take this into account if you’ll be taking it with you from job site to job site.

Factors in Detail:

Now let’s discuss these 7 factors one by one in detail.

PSI Requirement for Air Hammer:

Most air hammers require at least 90 PSI of pressure to operate properly. Higher-pressure compressors will be able to generate more power, allowing the air hammer to work faster and with greater precision.

CFM Requirement for Air Hammer:

The CFM of your air compressor dictates how much air it can move per minute. Generally, it’s best to go with a compressor that has a minimum of 5 CFM in order to ensure you have enough power for your tasks.

Horsepower Requirement for Air Hammer:

The horsepower (HP) of the air compressor you select will determine how quickly it can deliver a consistent stream of air to your air hammer. Generally, the more HP your compressor has, the faster it will be able to perform its tasks.

Tank Size Requirement for Air Hammer:

The size of the air compressor tank plays an important role in determining its overall power output as well as how often you’ll need to stop work to let it recharge. A larger tank can handle more projects without requiring frequent recharging, while a smaller tank will require more breaks between tasks.

Flow Meter Requirement for Air Hammer:

A flow meter helps measure the amount of air being used by an air hammer so you know when it needs more air or if it’s using too much. The duty cycle rating of the compressor tells you what percentage of time the compressor can run before needing a break to cool down and recharge its tank.

Portability Requirement for Air Hammer:

If portability is important to you, consider the weight and size of your chosen air compressor as well as whether it will be able to fit in your vehicle. Larger compressors can be heavier and more difficult to move than smaller ones, so make sure to take this into account if you’ll often be moving your equipment from job site to job site.

Can I Use Small Air Compressor For Using Air Hammer?

Yes, you can use a small air compressor for using an air hammer. However, be sure to take into consideration the PSI, HP, tank size, CFM and flow meter ratings of your compressor in order to ensure that it has the necessary power. Additionally, check the duty cycle rating so you know how long it can run before needing to be recharged. If portability is important, then consider the weight and size of your chosen compressor in order to determine whether it will be able to fit in your vehicle.

Frequently Asked Questions

Question #1

What is the duty cycle rating of an air compressor?

The duty cycle rating is the percentage of time that an air compressor can run before needing a break to cool down and recharge the tank. Generally, this rating will be between 50-80%.

Question #2

What PSI is needed for running an air hammer with an air compressor?

Most air hammers require at least 90 PSI of pressure in order to operate properly.

Question #3

What HP is required for running an air hammer with an air compressor?

The horsepower (HP) of the chosen compressor will determine how quickly it can deliver a consistent stream of air to your air hammer. Generally, higher horsepower compressors will be able to generate more power, allowing your air hammer to work faster and with greater precision.

Question #4

What size tank is required for running an air hammer with an air compressor?

The size of the tank plays an important role in determining the overall power output as well as how often you’ll need to stop work to let it recharge. A larger tank can handle more projects without needing frequent recharging, while a smaller tank will require more breaks between tasks.

Question #5

What CFM is needed for running an air hammer with an air compressor?

The CFM (Cubic Feet per Minute) rating of your chosen compressor should be at least 5 or higher in order to ensure you have enough power for all your tasks.

Question #6

Do I need a flow meter for running an air hammer with an air compressor?

A flow meter helps measure the amount of air being used by your air hammer so you know when it needs more air or if it’s using too much. It is recommended to have one in order to maintain precision and accuracy while operating your tool.

Question #7

Is portability important for running an air hammer with an air compressor?

If portability is important to you, consider the weight and size of your chosen compressor as well as whether it will be able to fit in your vehicle. Larger compressors can be heavier and more difficult to move than smaller ones, so make sure to take this into account if you’ll often be moving your equipment from job site to job site.

Question #8

What type of maintenance is required for running an air hammer with an air compressor?

Proper maintenance of an air compressor is essential in order to ensure its longevity and proper functioning. This includes regularly checking the oil and filter, replacing worn out parts, lubricating the motor, clearing out any dust or debris and performing general inspections every few months.

Question #9

Can I use a small air compressor for using an air hammer?

Yes, you can use a small air compressor for an air hammer as long as it has enough power. Be sure to consider the PSI, HP, tank size, CFM and flow meter ratings of your compressor in order to determine if it will have enough power for the job.

Question #10

What other tools can I use with an air hammer?

An air hammer is a versatile tool that can be used for many different tasks, including grinding, sanding, chipping and cutting. Additionally, you can attach various accessories such as needles and chisels to customize it for certain projects. With the right attachments, you can use your air hammer for a variety of jobs.

Conclusion:

An air hammer is a powerful, convenient and versatile tool that can be used for many different tasks, from grinding to cutting. When choosing an air compressor for your air hammer, it’s important to consider its duty cycle rating, PSI, HP, size of tank and CFM. Additionally, you may need a flow meter if precision is important for the job and portability may also be something to take into account. Lastly, regular maintenance will ensure your air compressor remains in top condition. With the right setup and some knowledge on how to use it properly, you’ll find yourself making quick work of any project with an air hammer.