When it comes to laser welding, one of the most important factors is the size of the air compressor. This is because the air compressor is responsible for providing the laser with the power it needs to weld. If the air compressor is too small, it will not be able to provide enough power and the laser will not be able to weld. On the other hand, if the air compressor is too big, it will be too powerful and can damage the laser.

So, what size air compressor for laser welding do you need? The answer depends on a few factors, such as the type of laser, the power of the laser, and the material you will be welding.

What Size Air Compressor For Laser Welding

The first thing to consider is the power of the laser. A higher power laser will require a more powerful air compressor. The next thing to consider is the thickness of the material you’re welding. The thicker the material, the more air pressure you’ll need.

For laser welding, you’ll need an air compressor with a CFM rating of at least 2-8 and a PSI rating around 30-50. HP should be in the 5-10 range, and the tank size should be around 1-3 gallons or higher.

What Is Laser Welding?

Welding is a process that joins materials, usually metals or thermoplastics, by causing coalescence. This is often done by melting the workpieces and adding a filler material to form a pool of molten material (the weld pool) that cools to form a joint that is usually stronger than the base material. Welding is distinguished from other joining processes, such as brazing and soldering, which do not melt the base material.

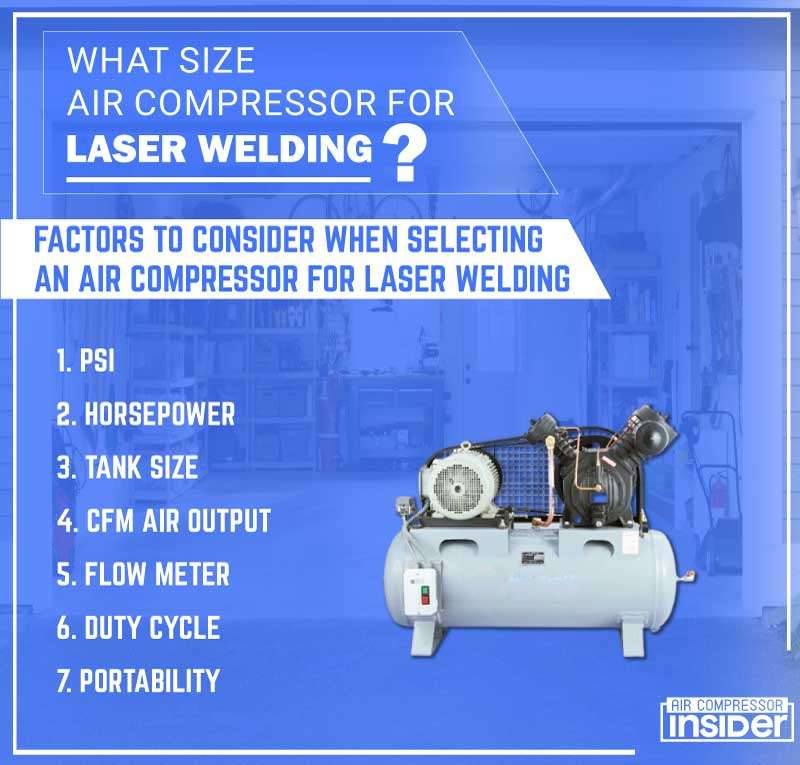

Important Factors to Consider When Selecting an Air Compressor for Laser Welding:

How Much PSI Is Required For Laser Welding?

If you’re thinking about using an air compressor to power your laser welding machine, you’ll need to make sure the unit can provide enough pressure. Most laser welders require between 30 and 40 PSI of pressure, so an air compressor with a maximum output of at least 50 PSI would be a good choice.

When using an air compressor for laser welding, it’s important to have a good air filtration system in place. This will help to remove any contaminants from the air that could potentially damage the laser or cause welding problems. It’s also a good idea to use an air regulator to help maintain a consistent pressure.

If you’re not sure whether your air compressor is up to the task of powering a laser welder, it’s always best to consult with the manufacturer. They will be able to advise you on the best way to set up your system and ensure that you have the right equipment for the job.

How Much CFM Is Required For Laser Welding?

When it comes to laser welding, one of the most important factors is the volume of air that is being moved by the compressor. This is typically measured in cubic feet per minute, or CFM. The amount of CFM required will vary depending on the type of laser welding system being used, as well as the material being welded.

For example, when welding aluminum, a laser welding system will typically require between 4 and 8 CFM of air. This is because aluminum is a very good conductor of heat, and the extra air flow helps to cool the weld area and prevent the material from melting.

When welding steel, on the other hand, a laser welding system will typically only require 2-4 CFM of air. This is because steel is not as good a conductor of heat, and the extra air flow is not as necessary to prevent the material from melting.

The amount of CFM required when using an air compressor for laser welding can also be affected by the size of the welding area. For example, if you are welding a large area, you will likely need more CFM than if you are welding a small area.

How Much Horse Power Is Required For Laser Welding?

The amount of horsepower required will vary depending on the specific laser welding application and the size of the air compressor.

For most laser welding applications, a minimum of 5 horsepower is required. However, for larger applications or those that require more power, an air compressor with 10 or more horsepower may be necessary. It is important to consult with a laser welding specialist to determine the specific horsepower requirements for your application.

When choosing an air compressor for laser welding, it is important to select one that is designed specifically for this purpose. Many air compressors on the market are not designed to handle the high volume of compressed air required for laser welding. As a result, they may overheat or break down during use.

What Tank Size Is Required For Laser Welding?

When it comes to laser welding, the size of the tank you’ll need will depend on a few factors. The first is the power of the laser you’re using. The higher the power, the more air you’ll need to supply to the laser. The second factor is the duration of the weld. The longer the weld, the more air you’ll need.

For most laser welding applications, a tank that can hold at least 30 gallons will be sufficient. If you’re using a high-powered laser or doing a lot of welding, you may need a larger tank.

The size of the tank is not the only thing to consider when using an air compressor for laser welding. You’ll also need to make sure the compressor can deliver enough air flow to meet the needs of the laser. Most laser welding applications require at least 4 CFM (cubic feet per minute).

If you’re not sure what size tank or compressor you need, consult with a laser welding expert. They can help you determine the best setup for your specific needs.

Is Portable Air Compressor Required For Laser Welding?

The answer is, it depends. If you’re only going to be doing occasional, small-scale laser welding, then a portable air compressor may be sufficient. However, if you’re planning on doing any serious welding with your laser, then you’ll need a dedicated air compressor that can provide a consistent, reliable flow of air.

There are a few things to keep in mind if you’re using a portable air compressor for your laser welding needs.

First, you’ll need to make sure that the compressor is powerful enough to provide the amount of air flow you need.

Second, you’ll need to be careful about where you place the compressor, as the heat from the laser can potentially damage it.

Overall, it’s not necessary to have a dedicated air compressor for laser welding if you’re only doing occasional, small-scale welding.

Benefits Of Using The Right Size Air Compressor For Laser Welding:

If you’re considering using a laser welder for your business, you may be wondering if an air compressor is necessary. The short answer is yes – an air compressor is an essential part of the laser welding process.

Here’s a look at some of the benefits of using an air compressor for laser welding:

1. Increased Precision:

One of the biggest benefits of using an air compressor for laser welding is the increased precision it offers. When welding with a laser, the heat is focused in a very small area. This means that even the slightest movement can cause the weld to be inaccurate.

2. Faster Welding Speeds:

Another benefit of using an air compressor for laser welding is the increased speed. When welding with a laser, the heat is focused in a very small area. This means that the weld can be completed in a fraction of the time it would take to weld with a traditional welding method.

3. Greater Control Over The Welding Process:

The air compressor provides greater control over the welding process by regulating the amount of air pressure that is applied to the welding torch. This allows the welder to control the speed of the welding process and the amount of heat that is applied to the metal. The air compressor is an essential piece of equipment for any welding shop.

4. Less Heat Input Into The Workpiece:

Air compressors are often used in laser welding applications because they can provide a consistent and controlled flow of air to the laser. This controlled flow of air can help to reduce the amount of heat input into the workpiece during the welding process.

It is also important to note that air compressors can be used to cool the laser during the welding process. This cooling can help to reduce the amount of heat input into the workpiece and help to prevent damage to the material.

5. Increased Productivity:

An air compressor can help to increase productivity in a number of ways.

Firstly, it can provide a consistent source of power to the laser welder, meaning that the welder can be used for longer periods of time without needing to stop for a break.

Secondly, an air compressor can help to keep the laser welder cool, meaning that it can be used for more complex welding jobs without overheating.

Finally, an air compressor can be used to clean the welding area, helping to prevent contamination and ensuring a high quality weld.

Are Air Compressors Better For Laser Welding?

There are several reasons why air compressors are better for laser welding:

1. Air compressors are less expensive to operate than other types of compressors.

2. Air compressors produce less heat, which means that the weld will be cooler and less likely to warp the material.

3. Air compressors are more efficient than other types of compressors, so they use less energy and produce less heat.

4. Air compressors are easier to maintain than other types of compressors.

5. Air compressors are more versatile than other types of compressors and can be used for a variety of applications.

If you’re looking for a compressor that will provide less heat input into the workpiece during laser welding, then an air compressor is the best option.

Conclusion:

After researching the various types and sizes of air compressors, it is evident that the best size air compressor for laser welding is one that is portable and can be easily moved from one location to another. The size of the compressor will also depend on the specific needs of the user.

For most laser welding projects, a small or medium-sized air compressor will suffice. However, if you plan on using your air compressor for heavy-duty tasks, you may need a larger unit. It is also important to consider the CFM (cubic feet per minute) rating of the air compressor, as this will determine how much air is delivered to the tool.