When choosing an air compressor for an orbital sander, you’ll need to consider the size of air compressor and the CFM rating. The size of the unit is important because you’ll need to make sure it will fit in the space you have available. The CFM rating is important because it will determine how much air the unit can move.

The size of the air compressor tank is also important. If you’ll be using the sander for extended periods of time, you’ll need a larger tank so the unit doesn’t have to work as hard. A larger tank will also allow you to store more air, which is helpful if you have a lot of projects that require an orbital sander.

What Size Air Compressor For Orbital Sander

When it comes to choosing best size air compressor for orbital sander, the most important factor to consider is the CFM (cubic feet per minute). This is a measure of the amount of air the compressor can deliver. The higher the CFM, the more power the compressor has.

- What Size Air Compressor For Orbital Sander

- What Is An Orbital Sander?

- Types of Orbital Sander:

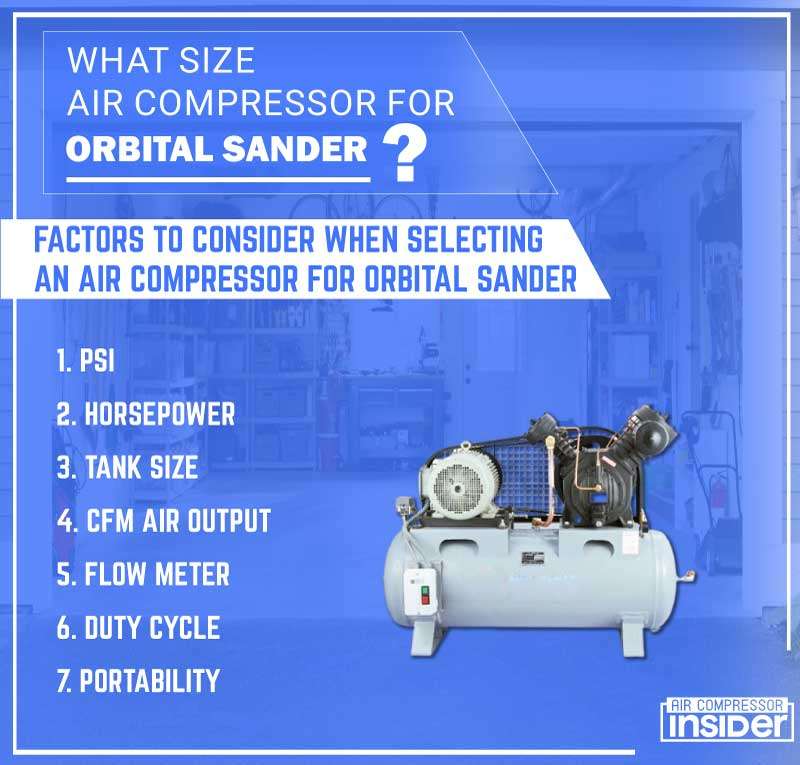

- Important Factors to Consider When Selecting an Air Compressor for Orbital Sander:

- What Are The Benefits Of Using An Air Compressor For Orbital Sander?

- How to Use Orbital Sander With An Air Compressor?

- Safety Precautions to Follow When Using Orbital Sander with Air Compressor:

- Conclusion:

For orbital sander, you’ll need an air compressor with a CFM rating of at least 3-4 and a PSI rating around 90-120. HP should be in the 3-5 range, and the tank size should be around 3-4 gallons or higher.

What Is An Orbital Sander?

An orbital sander is a power tool that uses abrasive paper or pads to sand down surfaces. It gets its name from the circular motion of the sanding pad, which is similar to the motion of the planets around the sun.

The orbital sander is a very versatile power tool and can be used for a variety of tasks in a woodshop, such as removing paint, varnish, stains, and small imperfections from wood surfaces; preparing metal surfaces for painting; and sanding down rough surfaces to create a smooth finish.

Types of Orbital Sander:

There are many different types of orbital sanders on the market, each with their own unique benefits and drawbacks. In this article, we’ll be taking a closer look at the different types of orbital sanders to help you choose the best one for your needs.

1. Hand-Held Orbital Sander

2. Benchtop Orbital Sander

3. Floor-Standing Orbital Sander

1. Hand-Held Orbital Sander:

These are the most common type of orbital sander, and they’re great for a variety of tasks. The biggest advantage of a hand-held orbital sander is that they’re very versatile and can be used for a variety of different projects.

2. Benchtop Orbital Sander:

These sanders are designed to be used on a workbench or other flat surface. Benchtop orbital sanders are typically larger and more powerful than hand-held orbital sanders, making them ideal for larger projects.

3. Floor-Standing Orbital Sander:

These sanders are designed for use on floors, and they’re typically the most powerful type of orbital sander. Floor-standing orbital sanders are great for large projects, but they can be a bit more difficult to maneuver.

Also Read: What Size Air Compressor For DA Sander

Important Factors to Consider When Selecting an Air Compressor for Orbital Sander:

How Much PSI Is Required For Orbital Sander?

If you’re using an air compressor to power an orbital sander, you’ll need to make sure that the compressor is able to generate enough pressure to keep the sander running smoothly. Most orbital sanders require between 90 and 120 PSI to operate properly, so you’ll need to ensure that your compressor can generate at least that much pressure. If you’re not sure how much pressure your compressor can generate, consult the owner’s manual or contact the manufacturer.

How Much CFM Is Required For Orbital Sander?

When it comes to orbital sanders, one of the most important factors to consider is the amount of CFM (cubic feet per minute) that the air compressor can provide. This is because the sander will require a continuous supply of air in order to operate properly.

The amount of CFM required will vary depending on the size of the sander and the type of material you are sanding. For example, a small sander will require less CFM than a large sander. Similarly, sanding a soft material will require less CFM than sanding a hard material.

As a general rule of thumb, you should look for an air compressor that can provide at least 4 CFM of air flow. This will ensure that your sander has enough air to operate properly, regardless of the size or type of material you are working with.

How Much Horse Power Is Required For Orbital Sander?

The answer depends on a few factors, including the size of the orbital sander and the pressure rating of the air compressor. A small orbital sander may only require 3-5 horsepower, while a larger sander could need up to 10 horsepower. The pressure rating is also important, as a high pressure air compressor will require more horsepower to run effectively.

To get an idea of the horsepower required for your specific air compressor and orbital sander combo, it’s best to consult the manufacturer’s recommendations. But in general, you should expect to need at least 5 horsepower when using an air compressor to power an orbital sander.

What Tank Size Is Required For Orbital Sander?

If you’re looking to use an air compressor for your orbital sander, you’ll need to make sure you have the right size tank. Depending on the size of your sander and the type of work you’ll be doing, you’ll need a tank that’s large enough to provide the necessary air flow.

For small sanders, a 3 gallon air compressor should be sufficient. If you’re using a larger sander, or if you’ll be doing a lot of work, you’ll need a larger tank. A 6-gallon tank will provide more than enough air flow for most applications.

When choosing an air compressor for your orbital sander, make sure to select one that has enough power to run the sander. A 3-horsepower air compressor should be sufficient for most sanders. If you’re using a larger sander, or if you’ll be doing a lot of work, you’ll need a more powerful air compressor.

Make sure to choose an air compressor with a tank that’s the right size for your needs. A too small tank will result in insufficient air flow, while a too large tank will be more expensive and difficult to move around.

Is Portable Air Compressor Required For Orbital Sander?

Portable air compressors are not required when using an air compressor for an orbital sander. However, they can be very useful in certain situations. For example, if you are using your orbital sander in a remote location where there is no power source, a portable air compressor can be used to power your sander. Additionally, if you are using your orbital sander in a dusty environment, a portable air compressor can be used to blow the dust away from your work area.

What Are The Benefits Of Using An Air Compressor For Orbital Sander?

Air compressors can make orbital sanders more powerful and efficient. When using an air compressor, the sander can spin faster and sand more aggressively without overloading the motor. This makes the job go quicker and results in a smoother finish.

In addition, an air compressor can be used to power other tools such as impact wrenches and ratchets. This can be useful if you need to use multiple tools for a job and don’t have a lot of space to store them.

Overall, using an air compressor with an orbital sander can be a great way to improve the performance of the tool and make your job easier.

How to Use Orbital Sander With An Air Compressor?

If you’re looking for a way to quickly and easily sand down wood, metal, or other materials, an orbital sander with an air compressor is a great option. Here’s a step-by-step guide on how to use one:

Step 1: Attach the sander to the air compressor. Make sure that the air compressor is turned off before doing this.

Step 2: Turn on the air compressor and set it to the desired pressure.

Step 3: Hold the sander against the material you want to sand. Start with light pressure and increase as needed.

Step 4: Move the sander in a circular motion.

Step 5: When you’re finished, turn off the air compressor and disconnect the sander.

Safety Precautions to Follow When Using Orbital Sander with Air Compressor:

When it comes to sanding surfaces, an orbital sander is one of the most effective tools you can use. But as with any power tool, there are certain safety precautions you need to take when using an orbital sander with an air compressor.

First and foremost, always wear proper eye and ear protection when using an orbital sander. The high-speed rotation of the sanding pad can generate a lot of dust and debris, which can be dangerous if it gets in your eyes. ear protection is also important to protect your hearing from the loud noise generated by the orbital sander.

Second, be sure to keep the orbital sander moving at all times. If you stop the sander in one spot for too long, you run the risk of damaging the surface you’re sanding.

Third, don’t apply too much pressure when using the orbital sander. Let the sander do the work – applying too much pressure will only damage the surface and make your job harder.

Finally, always unplug the orbital sander and air compressor before making any adjustments or repairs. Once you’re finished using the orbital sander, be sure to clean up any dust or debris to avoid any accidents.

Conclusion:

After researching the various types and sizes of air compressors, it is evident that the best size air compressor for an orbital sander is one that is portable and can be easily moved from one location to another. The size of the compressor will also depend on the specific needs of the user.

For most orbital sanders, a small or medium-sized air compressor will suffice. However, if you plan on using your orbital sander for heavy-duty tasks, you may need a larger air compressor. It is also important to consider the CFM (cubic feet per minute) rating of the air compressor, as this will determine how much air is delivered to the tool.