When it comes to choosing an air compressor, one of the most important considerations is the size of the air compressor. This is especially true when choosing an air compressor for a pressure pot. The size of the compressor you need will depend on a number of factors, including the size of the pressure pot, the type of air compressor, and the intended use for the compressor.

Air compressors come in a variety of sizes, from small, portable units to large, industrial-sized machines. The size of the compressor you need will depend on the size of the pressure pot you are using. A small pressure pot will require a smaller compressor, while a larger pressure pot will need a larger high pressure air compressor.

The type of air compressor you choose will also affect the size of the unit you need. For example, a piston air compressor will be larger than a diaphragm air compressor. If you are using a pressure pot for commercial or industrial applications, you will need a larger, more powerful compressor.

What Size Air Compressor For Pressure Pot

The size of air compressor you need to use a pressure pot will vary depending on the size of the pot and the pressure you need to achieve. For example, a small pressure pot may only require a 3 gallon air compressor, while a larger pot may require a 5 or 6 gallon compressor. The pressure you need to achieve will also play a role in determining the size air compressor you need – if you need to generate a lot of pressure, you’ll need a larger air compressor.

- What Size Air Compressor For Pressure Pot

For pressure pot, you’ll need an air compressor with a CFM rating of at least 1-5 and a PSI rating around 90. HP should be 1, and the tank size should be around 1-2 gallons or higher.

What Is A Pressure Pot?

A pressure pot is a type of pressure vessel that is used to store and pressurize liquids and gases. Pressure pots are often used in applications where high pressure is required, such as in hydraulic and pneumatic systems. Pressure pots can be made from a variety of materials, including metals, plastics, and composites.

Why Pressure Pots Are Used?

Pressure pots are used in a variety of industries and applications. Some common examples include:

Automotive industry:

Pressure pots are used in a variety of automotive applications, such as in airbags, brakes, and power steering systems.

Aerospace industry:

Pressure pots are used in aircraft and rockets to store and pressurize fluids.

Food and beverage industry:

Pressure pots are used in food and beverage processing to pasteurize liquids and carbonate beverages.

Chemical industry:

Pressure pots are used in chemical processing to store and pressurize chemicals.

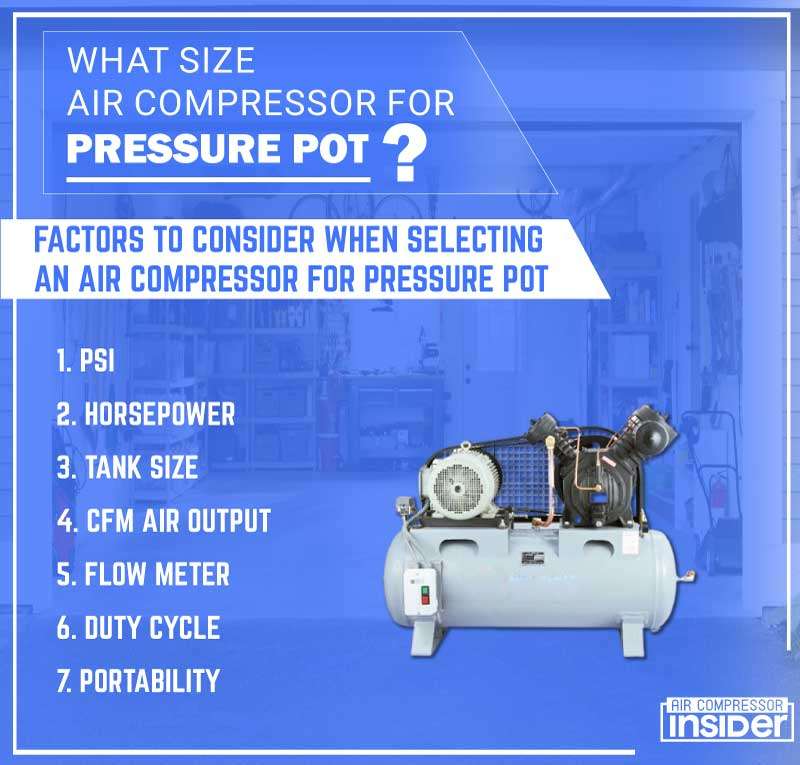

Important Factors to Consider When Selecting an Air Compressor for Pressure Pot:

How Much PSI Is Required For Pressure Pot?

When using an air compressor for a pressure pot, the amount of PSI (pounds per square inch) required will depend on the specific application. For example, if you are using the compressor to power a nail gun, you will need a higher PSI than if you were using it to inflate a tire. The size of the pressure pot also plays a role in how much PSI is required.

Generally speaking, you will need an air compressor that can generate at least 90 PSI to use with a pressure pot. However, it is always best to consult the specific instructions for your pressure pot to determine the minimum PSI required.

How Much CFM Is Required For Pressure Pot?

When using an air compressor for a pressure pot, it is important to ensure that you have enough CFM (cubic feet per minute). The amount of CFM required will vary depending on the size of the pressure pot, but a good rule of thumb is to have at least 1 CFM for every gallon of capacity. For example, if you are using a 5 gallon pressure pot, you should have at least 5 CFM of air flow.

If you do not have enough CFM, the air compressor will not be able to keep up with the demand and the pressure pot will not work properly. In addition, if the pressure pot is not vented properly, it can build up too much pressure and explode.

To ensure that you have enough CFM, it is important to consult the owner’s manual for your air compressor and pressure pot. If you are still unsure, it is always best to err on the side of caution and choose an air compressor with a higher CFM rating.

How Much Horse Power Is Required For Pressure Pot?

In order to determine how much horsepower is required when using an air compressor for pressure pot, you will need to know the required air flow rate and desired pressure.

The required air flow rate is typically measured in cubic feet per minute (cfm). The desired pressure is typically measured in pounds per square inch (psi).

To calculate the required horsepower, multiply the air flow rate by the desired pressure and divide by 4500.

For example, if you need an air flow rate of 10 cfm at a pressure of 90 psi, the calculation would be as follows:

10 cfm x 90 psi = 900

900 / 4500 = 0.2 hp

Therefore, you would need at least 0.2 hp to operate a pressure pot with a air compressor.

What Tank Size Is Required For Pressure Pot?

The size of the tank on your air compressor will have a direct impact on the pressure that is available for your tools. A small tank will not be able to store as much air as a larger tank, and therefore the pressure will not be as high.

If you are using a pressure pot, you will need to make sure that the tank on your air compressor is large enough to provide enough pressure. Otherwise, your pressure pot will not work as effectively.

Is Portable Air Compressor Required For Pressure Pot?

Portable air compressors are a great way to keep your pressure pot full of air. If you have an air compressor that you use for other purposes, you may not need to buy a portable air compressor. But if you only use your air compressor for your pressure pot, a portable air compressor is a good investment.

A portable air compressor will allow you to take your pressure pot with you wherever you go. If you have a workshop at home, you can use your portable air compressor to fill your pressure pot before you leave for work. If you work in a garage, you can use your portable air compressor to fill your pressure pot before you head home.

What Are The Benefits Of Using A Pressure Pot With An Air Compressor?

If you’re looking for a way to speed up your painting projects, you may want to consider using a pressure pot with an air compressor. This type of setup can help you achieve a professional-looking finish in a fraction of the time it would take to hand-paint your project.

Here are some of the benefits of using a pressure pot with an air compressor:

1. Speed:

A pressure pot with an air compressor can help you complete your painting project much faster than if you were to hand-paint it. This is because the air compressor will provide a constant stream of air to the pressure pot, which will allow you to apply the paint much faster.

2. Efficiency:

A pressure pot with an air compressor is also much more efficient than hand-painting. This is because you won’t have to stop and start the paint job as often, which can save you a lot of time.

3. Quality:

When you use a pressure pot with an air compressor, you can be sure that the paint job will be of a much higher quality. This is because the air compressor will evenly distribute the paint, which will give you a smoother, more even finish.

4. Saves Time:

Using a pressure pot can help to reduce the amount of time that it takes to complete a paint job, as well as the amount of paint that is required.

What Are The Safety Precautions To Take When Using A Pressure Pot With Air Compressor?

Working with a pressure pot and air compressor can be dangerous if you don’t take the proper safety precautions. Here are some things to keep in mind when using this type of equipment:

1. Always wear safety glasses or goggles when working with a pressure pot and air compressor.

2. Make sure the pressure pot and air compressor are properly grounded before use.

3. Never exceed the maximum pressure rating for the pressure pot or air compressor.

4. When disconnecting the pressure pot from the air compressor, always release the pressure from the pot first before disconnecting the hoses.

5. Be sure to properly vent the pressure pot before use to avoid explosive conditions.

6. Never leave a pressure pot and air compressor unattended while in use.

7. Always disconnect the power to the air compressor before performing any maintenance on the pressure pot.

8. Be familiar with the operating instructions for the pressure pot and air compressor before use.

By following these safety precautions, you can help ensure a safe and successful experience when using a pressure pot and air compressor.

Conclusion:

After researching the various types and sizes of air compressors, it is evident that the best size air compressor for a pressure pot is one that is portable and can be easily moved from one location to another. The size of the compressor will also depend on the specific needs of the user.

For most pressure pots, a small or medium-sized air compressor will suffice. However, if you plan on using your pressure pot for heavy-duty tasks, you may need a larger unit. It is also important to consider the CFM (cubic feet per minute) rating of the air compressor, as this will determine how much air is delivered to the tool.