Sandblasting is a time-consuming and precise task which requires special tool, an air compressor. If you’re intending to do some sandblasting soon, having the right size air compressor for the job is essential. Knowing what size air compress for sandblasting is right for your project can make all the difference in ensuring your success and meeting deadlines.

In this guide, you’ll find all of the information needed to know the right size air compressor for sandblasting, from learning exactly what requirements must be met all the way up to purchasing tips that could save time and money. So let’s get started!

What Size Air Compressor For Sandblasting

- What Size Air Compressor For Sandblasting

- What Is Sandblasting?

- Types of Sandblasting:

- Tips For Purchasing The Right Size Air Compressor For Sandblasting:

- 7 Important Factors to Consider When Selecting an Air Compressor for Sandblasting:

- Factors in Detail:

- PSI Required For Sandblasting With An Air Compressor:

- HP Required For Sandblasting With An Air Compressor:

- Tank Size Required For Sandblasting With An Air Compressor:

- CFM Required For Sandblasting With An Air Compressor:

- Flow Meter Required For Sandblasting With An Air Compressor:

- Duty Cycle Required For Sandblasting With An Air Compressor:

- Portability Required For Sandblasting With An Air Compressor:

- Can I Use Small Air Compressor For Sandblasting?

- How Can I Make Sure My Air Compressor Is Working Properly?

- Advantages Of Using An Air Compressor For Sandblasting:

- Frequently Asked Questions

- Conclusion:

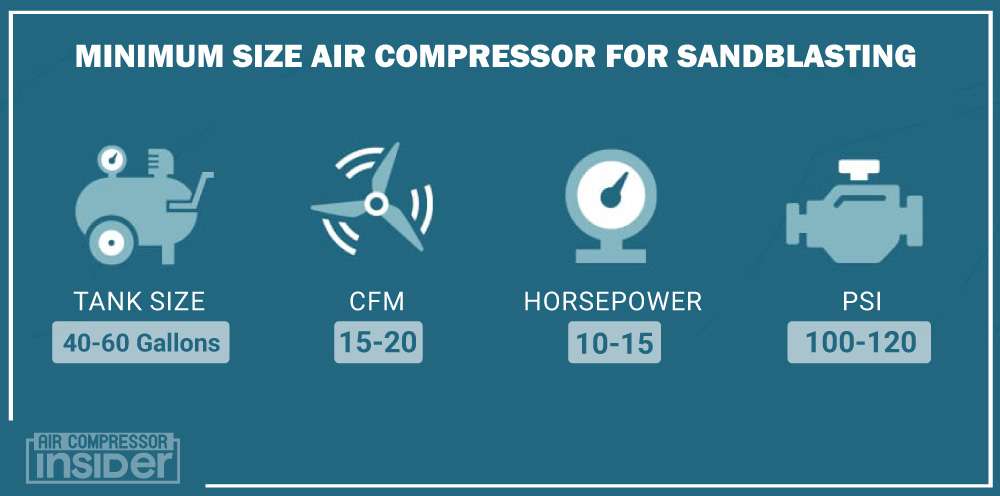

For sandblasting, you’ll need an air compressor with a CFM rating of at least 15-20 and a PSI rating around 100-120. HP should be in the 10-15 range, and the tank size should be around 40-60 gallons or higher.

What Is Sandblasting?

Sandblasting can be done for a variety of purposes, from creating a smooth finish on wood or steel to graffiti removal. As such, the size air compressor needed will depend on the size of sandblaster and the type of sandblasting being performed.

This process includes sand particles or dry silica abrasive particles called abrasive blasting. The abrasive particles are sprayed on the surface with such high pressure that it looks like a blast. That is why it is called sandblasting. As soon as these abrasive sand particles hit the surface with pressure, it clears the surface from any contaminants with ease.

Types of Sandblasting:

Sandblasting can be done for a variety of purposes, from creating a smooth finish on wood or steel to graffiti removal. As such, the size air compressor needed will depend on the type of sandblasting being performed.

Generally speaking, there are four main types of sandblasting:

1- Light Duty Sandblasting

2- Medium Duty Sandblasting

3- Heavy Duty Sandblasting

4- Industrial Sandblasting

1. Light Duty Sandblasting:

Light Duty Sandblasting is ideal for projects that don’t require too much power or pressure, such as prepping surfaces for paint or restoring furniture. For this type of sandblasting, a compressor with 4 HP and 6 CFM at 90 PSI will be enough. Any air compressor bigger than this would be unnecessary and could end up costing more than necessary.

2. Medium Duty Sandblasting:

Medium Duty Sandblasting is suitable for medium-sized projects where more power is needed, such as removing rust from metal surfaces or cleaning concrete walls. For this type of sandblasting, you’ll need a compressor with 6 HP and 8 CFM at 90 PSI. This will provide you with enough power to complete your project quickly and effectively.

3. Heavy Duty Sandblasting:

Heavy duty sandblasting is needed for large projects such as removing multiple layers of paint or corrosion from machinery. For this type of sandblasting, a compressor with 10 HP and 12 CFM at 90 PSI is the best choice. This type of air compressor will give you the power and pressure to efficiently get through even the toughest jobs.

4. Industrial Sandblasting:

Industrial sandblasting requires an even more powerful air compressor than heavy duty sandblasting to handle the most demanding applications such as removing thick layers of rust from large machinery. For this type of sandblasting, you’ll need an air compressor with 15 HP and 20 CFM at 90 PSI in order to ensure a successful end result.

Tips For Purchasing The Right Size Air Compressor For Sandblasting:

When purchasing an air compressor for sandblasting, it is important to take into account several factors:

– The pressure rating of the compressor should match your needs (4 HP, 6 HP, 10 HP or 15 HP).

– You should also make sure that the CFM rating is equal or greater than what you require for your project.

– Lastly, be aware that some compressors come with a built-in aftercooler, which is an important feature to reduce the moisture in the compressed air.

7 Important Factors to Consider When Selecting an Air Compressor for Sandblasting:

When selecting an air compressor for sandblasting, here are some important factors to consider:

PSI (pounds per square inch):

The higher the PSI, the greater the pressure of the compressor.

HP (horsepower):

This indicates how powerful your air compressor is. A larger HP rating means more power.

Tank Size:

The bigger the tank size, the longer you can work uninterrupted.

CFM (cubic feet per minute):

This refers to how much air the compressor can supply in a given time period and should be equal or greater than what you need for your project.

Flow Meter:

This measures the rate at which air is used from your compressor and helps you to monitor the pressure of the air being used.

Duty Cycle:

This refers to the time for which your compressor can operate in a given period before it needs rest or maintenance.

Portability:

Depending on your project, you may need an air compressor that is easy to transport. There are lightweight and portable models available on the market.

Selecting the right size air compressor for sandblasting can make all the difference between a successful sandblasting project and one that turns into a disaster. Following these tips will help ensure that you select the right size air compressor to get the job done quickly and efficiently!

Factors in Detail:

Now let’s discuss these factors one by one in detail.

PSI Required For Sandblasting With An Air Compressor:

The higher the PSI, the greater the pressure of the air compressor. For light duty sandblasting, you’ll need an air compressor with a PSI rating of 90 or more. For medium and heavy duty sandblasting, you’ll need a minimum of 100PSI while industrial-grade compressors require a PSI rating of 120 or more.

HP Required For Sandblasting With An Air Compressor:

This indicates how powerful your air compressor is and will determine the size and weight of your project. As mentioned above, light duty projects require 4 HP while medium to heavy duty projects require 6 HP or 10 HP respectively. Industrial-grade sandblasting requires 15 HP in order to ensure a successful end result.

Tank Size Required For Sandblasting With An Air Compressor:

The size of your tank determines how long you can work uninterrupted. For light duty sandblasting, a tank size of 40-gallon should be enough to complete the project in one go. However, for medium and heavy duty projects, you’ll need a bigger tank (60 gallon or more) to ensure that you have enough air supply for the duration of the job.

CFM Required For Sandblasting With An Air Compressor:

This refers to how much air the compressor can supply in a given time period. The CFM rating should be equal or greater than what you require for your project in order to ensure optimal results. For light duty sandblasting, you’ll need a minimum of 15 CFM at 90 PSI. Medium and heavy duty projects require 20 CFM or more.

Flow Meter Required For Sandblasting With An Air Compressor:

This measures the rate at which air is used from your compressor and helps to monitor the pressure of the air being used. This ensures that there are no sudden drops in pressure which could damage your project or put too much strain on your machine. Having a flow meter can help you adjust the pressure as needed for optimal results.

Duty Cycle Required For Sandblasting With An Air Compressor:

The duty cycle refers to how long your compressor can run in a given time period before it needs to rest or maintenance. When selecting an air compressor for sandblasting, you’ll want to make sure that its duty cycle is suitable for your project’s requirements.

Portability Required For Sandblasting With An Air Compressor:

Depending on your project, you may need an air compressor that is easy to transport. There are lightweight and portable models available on the market which can help save time and money when moving from one job site to another. These compressors are also ideal if you need to take your equipment with you on a trip.

Can I Use Small Air Compressor For Sandblasting?

Yes, you can use a small air compressor for sandblasting, but you will need to make sure that it meets the necessary requirements. Generally speaking, the minimum requirements are 4 CFM at 40 PSI and a working pressure range between 20-60 PSI.

If your air compressor does not meet these requirements, then it may not be suitable for sandblasting applications. It is also important to note that using an air compressor for sandblasting cabinet could result in poor performance and even damage to the sandblasting equipment.

Therefore, it is always best to use an air compressor with a higher horsepower rating than what is recommended for your specific application.

How Can I Make Sure My Air Compressor Is Working Properly?

1. Ensure the air compressor is clean and free from any dirt or debris that could impede its performance.

2. Check the motor for any loose bolts, wires, or components that need to be tightened or replaced.

3. Test the pressure gauge on the air compressor to ensure that it is giving a correct reading.

4. Check all hoses, connections and fittings for wear and tear or any other damage.

5. Bleed the pressure off of the unloader valve if necessary.

6. Make sure your air filter is clean and free from debris.

7. Make sure the air intake valve is open and operating properly.

8. Check the oil levels in your compressor regularly and change it if necessary.

9. Perform a trial run of your air compressor to make sure it is performing as expected before use.

10. Have a professional inspect and service your air compressor on a regular basis to keep it running smoothly.

Advantages Of Using An Air Compressor For Sandblasting:

Using an air compressor for sandblasting can be more efficient than other methods. It allows you to control the pressure of the air and adjust it according to your needs. This provides greater precision and accuracy in your work, resulting in better quality end results. Air compressors are also relatively inexpensive and easy to maintain, making them a great choice for sandblasting jobs.

Frequently Asked Questions

Question #1

What PSI is required for sandblasting with an air compressor?

For light duty sandblasting, you’ll need an air compressor with a PSI rating of 90 or more. For medium and heavy duty sandblasting, you’ll need a minimum of 100PSI while industrial-grade compressors require a PSI rating of 120 or more.

Question #2

What HP is required for sandblasting with an air compressor?

Light duty projects require 4HP while medium to heavy duty projects require 6HP or 10HP respectively. Industrial-grade sandblasting requires 15 HP in order to ensure a successful end result.

Question #3

What tank size is required for sandblasting with an air compressor?

For light duty sandblasting, a tank size of 40-gallon should be enough to complete the project in one go. However, for medium and heavy duty projects, you’ll need a bigger tank (60 gallon or more) to ensure that you have enough air supply for the duration of the job.

Question #4

What CFM is required for sandblasting with an air compressor?

The CFM rating should be equal or greater than what you require for your project in order to ensure optimal results. For light duty sandblasting, you’ll need a minimum of 15CFM at 90PSI. Medium and heavy duty projects require 20CFM or more.

Question #5

Why is portability important when selecting an air compressor for sandblasting?

Depending on your project, you may need an air compressor that is easy to transport. There are lightweight and portable models available on the market which can help save time and money when moving from one job site to another. These compressors are also ideal if you need to take your equipment with you on a trip.

Question #6

Are there any advantages of using an air compressor for sandblasting?

Yes! Using an air compressor for sandblasting can be more efficient than other methods. It allows you to control the pressure of the air and adjust it according to your needs. This provides greater precision and accuracy in your work, resulting in better quality end results. Air compressors are also relatively inexpensive and easy to maintain, making them a great choice for sandblasting jobs.

Question #7

Are there any drawbacks of using an air compressor for sandblasting?

The only major drawback is that air compressors require maintenance from time to time in order to keep them running effectively. Additionally, if you’re working on larger projects, then you’ll need a powerful machine with high capacity tanks which can be more expensive than smaller models with lower capacity tanks.

Question #8

How often should I service my air compressor?

Generally speaking, it’s recommended to service your air compressor at least once every two years. However, if you’re using it frequently for sandblasting or other tasks then it might be beneficial to have it serviced more often in order to ensure optimal performance and prevent premature breakdowns. It’s always best to check the manufacturer’s instructions for specific maintenance advice.

Question #9

What safety precautions should I take when using an air compressor for sandblasting?

Sandblasting can be dangerous if done without the proper safety measures in place. Wear protective clothing, goggles and a face shield to protect yourself from any debris or dust generated by the sandblaster. Additionally, make sure that you’re familiar with your air compressor and how to operate it safely before starting the job. It’s also important to check all connections regularly and ensure that the pressure is at a safe level.

Question #10

What are some tips for successful sandblasting with an air compressor?

Before you start your project, make sure that your equipment is properly adjusted and set-up according to your needs. Pay attention to details such as the nozzle size and pressure of the air, as these can affect the quality of your results. Additionally, be aware of any potential hazards and take all necessary safety precautions when using an air compressor for sandblasting. Finally, monitor your progress regularly and make adjustments as needed in order to ensure that you’re getting the best possible outcome.

Conclusion:

Using an air compressor for sandblasting is a great way to create precise and quality results. Knowing what size air compress for sandblasting you need, the importance of portability, advantages, drawbacks and safety precautions can help ensure that your project runs smoothly and efficiently with optimal end results. Regular servicing is required to keep the machine running effectively and it’s important to pay attention to details such as nozzle size and pressure when using an air compressor for sandblasting.