If you’re planning on scuba diving, one of the most important pieces of equipment is an air compressor. Air compressors come in all shapes and sizes, so it can be difficult to determine what size air compressor for scuba diving is right for your needs. In this article, we’ll cover what size air compressor is ideal for scuba diving and how to choose the right one.

What Size Air Compressor For Scuba Diving

The size of the air compressor you need depends on the type of scuba diving you’ll be doing. If you plan to go deep sea or cave diving, a larger, more powerful compressor may be necessary to efficiently fill your tank. Shallow water dives require less pressure and therefore can use a smaller compressor.

Most recreational divers will not need any large compressors and can get by with an average sized unit for their purposes. An average-sized air compressor is usually around 3 horsepower (hp) or higher; these units should handle most shallow dive depths without issues.

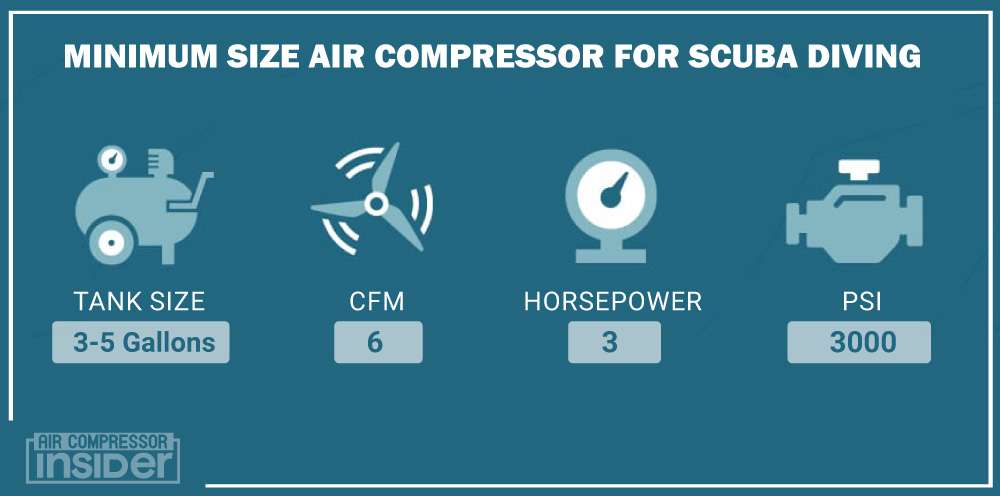

For scuba diving, you’ll need an air compressor with a CFM rating of at least 6 and a PSI rating should be atleast 3000. HP should be 3, and the tank size should be around 3-5 gallons or higher.

What Is A Scuba Diving?

Scuba diving is a form of underwater exploration. It involves using a tank and regulator to breathe air while descending into the depths of the ocean. Scuba divers can explore reefs, shipwrecks, dive deep sea trenches, and observe marine life up close.

For recreational scuba divers, it’s important to have an adequate amount of air onboard in order to remain safe and comfortable throughout the dive. This means having an air compressor that is large enough to fill your tanks adequately for each dive.

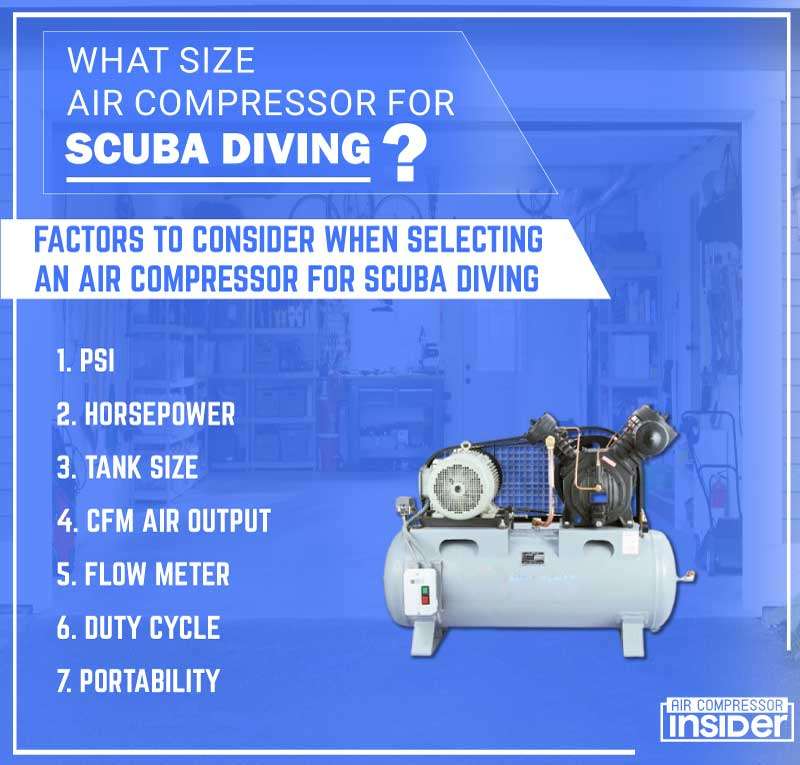

7 Important Factors to Consider When Selecting an Air Compressor For Scuba Diving:

When selecting an air compressor for scuba diving, it’s important to consider the following factors:

• PSI:

The pounds per square inch (PSI) capacity of the compressor is important as this will determine how much pressure the compressor can generate. Higher PSI compressors are best suited for deep dives where more compressed air is needed.

• HP:

Horsepower indicates how powerful a motor is and helps you understand how much air that motor can generate. Generally, 3hp or higher should be sufficient for most shallow dives.

• Tank Size:

Consider what tank size you need in order to store enough air onboard safely and comfortably. Larger tanks may require more powerful compressors to fill them.

• CFM:

Cubic feet per minute (CFM) indicates how quickly an air compressor can fill a tank. A higher CFM rating means the compressor is able to generate more air faster.

• Flow Meter:

Many modern compressors are equipped with flow meters, which allow you to monitor the amount of air that has been filled into your tanks. This is important for keeping track of your dive time and remaining in compliance with safety regulations.

• Duty Cycle:

The duty cycle of an air compressor refers to how long it can be used before needing a break or rest period. Air compressors for scuba diving should have a duty cycle of at least 50%.

• Portability:

If you plan to transport your air compressor, it’s important to consider its size and weight. A lightweight and compact air compressor will be easier to move around and store in small spaces.

Selecting the right size air compressor for scuba diving can make all the difference between a successful diving experience and one that turns into a disaster. Following these tips will help ensure that you select the right size air compressor to get the job done quickly and efficiently!

Can I Use Small Air Compressor For Scuba Diving?

Yes, small air compressors can be used for scuba diving as long as they meet the requirements listed above. A 3hp or higher compressor should provide adequate high pressure and CFM to fill tanks efficiently for most recreational dives. It’s also important to make sure that the compressor has enough capacity and duty cycle to handle multiple dives in one day if needed.

10 Advantages Of Using An Air Compressor For Scuba Diving:

1. Easily fill tanks:

Air compressors make it easier to fill scuba tanks quickly and efficiently.

2. Safe and reliable:

With an air compressor, you can trust that your tanks are filled correctly and safely with the right amount of pressure for each dive.

3. Monitor air levels:

Most modern air compressors have flow meters that allow divers to monitor the amount of air in their tanks at all times during a dive, helping them stay within safety guidelines.

4. Long-lasting performance:

High quality air compressors typically have a long lifespan and can be used multiple times without issue over several years with proper care and maintenance.

5. Flexibility:

An air compressor can be used for both shallow and deep dives, depending on its specs.

6. Accurate:

A good air compressor will fill tanks with the correct amount of pressure every time, ensuring proper safety and performance during a dive.

7. Cost-effective:

Air compressors are an economical way to keep your scuba tanks filled safely and reliably over a long period of time.

8. Portable:

Many air compressors for scuba diving are lightweight and portable, making them easy to transport or store in small spaces when not in use.

9. Convenience:

Air compressors make it convenient to quickly fill your scuba tanks before each dive with minimal effort required from you.

10. Environmentally friendly:

Air compressors are powered by electricity, so they do not produce any pollutants or exhaust fumes, making them a great choice for the environment.

Thus, using an air compressor for scuba diving is an efficient way to fill your tanks and stay within safety regulations without compromising your performance. It’s important to use a high quality compressor that meets the necessary requirements for your particular dive profile in order to ensure its long-term reliability and safe use underwater.

Frequently Asked Questions

Question #1

What is CFM rating?

The CFM (cubic feet per minute) rating of an air compressor indicates how quickly it can fill a tank. A higher CFM rating means the compressor is able to generate more air faster.

Question #2

What is a flow meter?

A flow meter is a device found on many modern compressors which allows you to monitor the amount of air that has been filled into your tanks. This helps divers keep track of their dive time and remain in compliance with safety regulations.

Question #3

What is duty cycle?

Duty cycle refers to how long an air compressor can be used before needing a break or rest period. Air compressors with a higher duty cycle are able to run for longer periods of time, which is beneficial if you plan on doing multiple dives in one day.

Question #4

What is the best type of air compressor for scuba diving?

The best type of air compressor for scuba diving depends on your particular dive profile and needs. A 3hp or higher compressor should provide adequate pressure and CFM to fill tanks efficiently for most recreational dives. It’s also important to make sure that the compressor has enough capacity and duty cycle to handle multiple dives in one day if needed.

Question #5

How much does an air compressor cost?

Prices vary depending on size, brand and features, but generally, you can expect to spend between $200 – $600 for a good quality air compressor.

Question #6

Are electric or gas powered compressors more reliable?

Electric air compressors are typically more reliable than gas-powered ones due to their low maintenance requirements. Additionally, electric models tend to last longer as they don’t require frequent refueling like gas-powered ones do.

Question #7

What safety precautions should be taken when using an air compressor for scuba diving?

It is important to always follow the manufacturer’s instructions when using an air compressor for scuba diving. Make sure that the tanks are filled with the correct amount of pressure, and wear protective gear such as gloves when filling tanks. Additionally, always make sure to check the air compressor before diving in order to ensure that it is working properly.

Question #8

How often should an air compressor be serviced?

Most manufacturers recommend servicing your air compressor every 2-3 years or if there are any signs of malfunctioning or decreased performance. This helps ensure that your machine runs at its best and lasts for a long time.

Question #9

What other accessories may be needed when using an air compressor for scuba diving?

It’s important to have adequate hoses and regulators on hand if you plan on filling tanks with an air compressor. You may also need to purchase a pressure gauge, gloves and other accessories depending on your dive profile.

Question #10

Are air compressors safe for underwater use?

Yes, air compressors are designed to be used in the water and meet all safety regulations. As long as you adhere to the manufacturer’s instructions, an air compressor should provide reliable performance and keep you within safety guidelines.

Conclusion:

Knowing what size air compressor for scuba diving is an important process. The size of compressor you need depends on the type of diving you’ll be doing and the tank size. Make sure to check the manufacturer’s specifications for maximum pressure ratings and other features before making a purchase. With the right air compressor, you can ensure your scuba diving trips are safe and enjoyable.